Exclusive: Ronald Wakes Up With Elon Musk. Here’s What Happened Next

It’s 5:30 am and I’m sitting in SolarQuotes office waiting for Elon Musk’s big battery day announcement. This is pretty early for me, so it had better be good. I don’t normally come into the office until 5:45 am.

I have no idea what Elon’s going to say except it’ll be about batteries. My guess is he’ll say Tesla is starting large scale production of a new and improved battery cell the size of one of those annoying Japanese mini-drink cans that only contain enough fluid to accentuate how thirsty you are. There will be a spiel about how great they are, but nothing unexpected.

Unless of course, Elon Musk manages to smash some more windows with his balls.

It Starts With A Shareholder Meeting

It’s now six o’clock and the presentation has started. The screen is showing battery cells being produced on an automated production line but there’s no sound. I was expecting it to gently fade in to alert people that things are getting underway, but there is nothing. Is this intentional? I see three possibilities:

- Tesla has screwed up.

- Something at my end is screwed up.

- Tesla is so screwed up they don’t realize this makes it look like they screwed up.

A guy is now coming up on stage… he’s about to tap the microphone… and yes! There’s sound! He is announcing the start of the shareholders meeting. I have to sit through this because Tesla haven’t given a separate time for the battery day announcement. I don’t think this is a smart move by Tesla. As Chancellor Otto Von Bismarck famously said:

“There are three things you do not want to see being made. Sausages, laws, and little baby Bismarcks.”

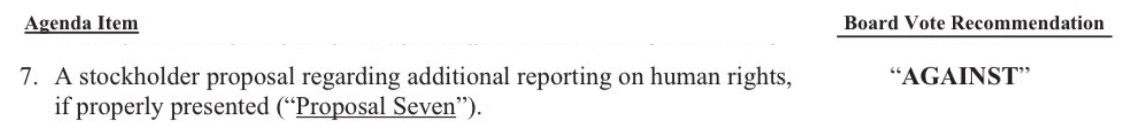

Do they really want to increase the number of people who witness the Tesla board recommending stockholders vote against increased human rights reporting?

The stockholder votes are now coming in and the results are there will be no increased human rights reporting for Tesla. What a beautiful sausage! I hope those working for Tesla and its suppliers don’t feel as though the board has just baby Otto Von Bismarcked them over.

Tesla Is Making A Profit!

Anyone running a small business can tell you the last thing you want to do is make a profit. It just attracts the wrong kind of attention. Like from the Tax Office. But big US companies seem to like it. Possibly because they don’t seem to pay tax anyway.

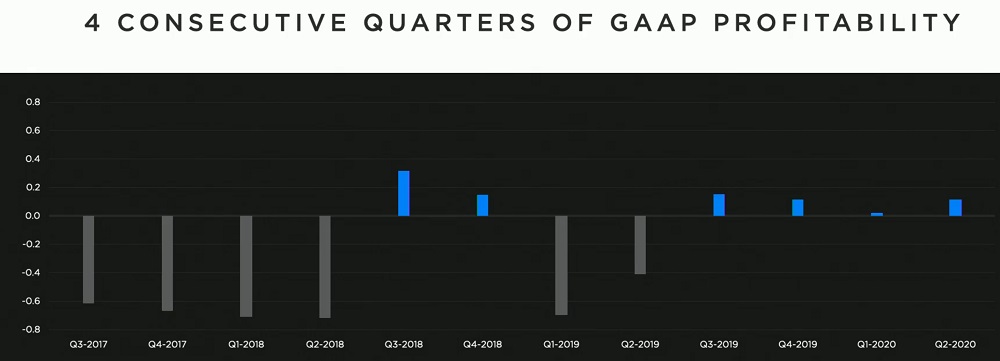

Tesla has turned a profit for a whole year now. It’s only equal to about 1% of their capital but that’s an infinitely greater amount than a loss.

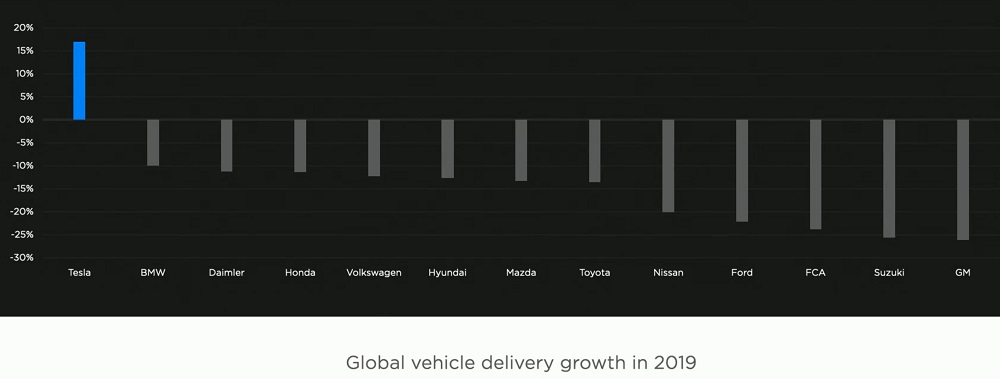

Their success does come at the cost of the internal combustion engine car industry. Thanks to Tesla and the pandemic economy, sales for conventional cars have been flushed so far down the drain you’ll need a toilet snake with a camera on the end to find them:

That’s all I have to say about the stockholder’s meeting. I’ll leave the rest up to the people who write business articles.

The Battery Day Announcement

The battery day announcement is about to begin and Elon Musk is greeted as he comes on stage by much honking of horns. The honking is because the event is being held in a car park with people sitting in cars on account of COVID. All the Tesla employees in the lot are wearing masks, which seems weird. You’d think Tesla employees would all be wearing disease proof space helmets by now. But it seems, when it comes to the coronavirus, there is no sacrifice Musk is not willing to let his workers make.

Elon Musk looks healthy. Being a billionaire must agree with him. Pictures of him in his 20s show he was balding, but now in his middle age he has a full head of hair. Amazing how that works. Also, not being on the edge of losing his company probably helps him seem more relaxed.

The presentation starts and Elon does a good job of public speaking by Elon Musk standards. His main promises are Tesla will:

- More than halve the cost of batteries by 2025, which will let them…

- Produce a fully autonomous electric car for $25,000 US in 3 years time.

The entire presentation was aimed at people like me who think:

“Tesla is nice and all, but I don’t see what is going to stop South Korea, Japan, and especially China — eating them alive.”

Everything said was aimed at keeping investors happy by explaining how Tesla is going to maintain a technological and competitive edge in the future.

I know the idea of a US company maintaining a technical lead in manufacturing rather than just in software or tax evasion seems weird these days, but we should remember Britain was well into its decline when they invented the automatic kettle in 1955, the ATM in 1967, the Goodies in 1970, and the World Wide Web in 1989.

Massive Battery Growth Required To Replace Fossil Fuels

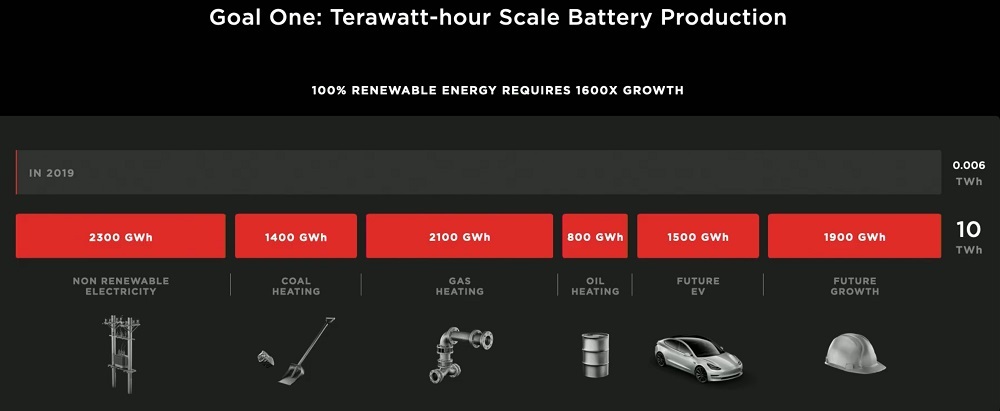

To electrify transport and allow renewable generation to expand, Elon said it would be necessary to start producing batteries on the terawatt-hour scale, which is a lot. One terawatt-hour of batteries could power Australia for about 40 hours.

He said the world needs 10 terawatt-hours of battery production annually to electrify all road transport over the next 15 years. This is plausible. If the average electric vehicle battery pack is 50 kilowatt-hours then 10 terawatt-hours would be enough for 200 million EVs. Only 92 million road vehicles were produced in 2019 but agricultural machinery and mining equipment can also be electrified and Tesla may be expecting future vehicle battery packs to be quite large.

To replace fossil fuels in other areas we were told an additional 10 terawatt-hours of batteries will have to be produced each year for 15 to 25 years, and Elon says the actual annual production required may be higher. This graphic breaks down where non-vehicle battery production will be going — although I don’t know why they have 1,500 gigawatts for “Future EV”:

Elon’s figures may not be correct. If people start using self-driving taxis rather than owning private cars the amount of battery capacity required for vehicles will be reduced. It’s also possible to eliminate fossil fuels from electricity generation without using any battery storage, but using batteries will make it a hell of a lot easier.

The actual amount of battery storage used will depend on cost and if Tesla cuts costs by more than half then Elon Musk’s estimates may turn out to be right.

Terawatt-hour Battery Factories

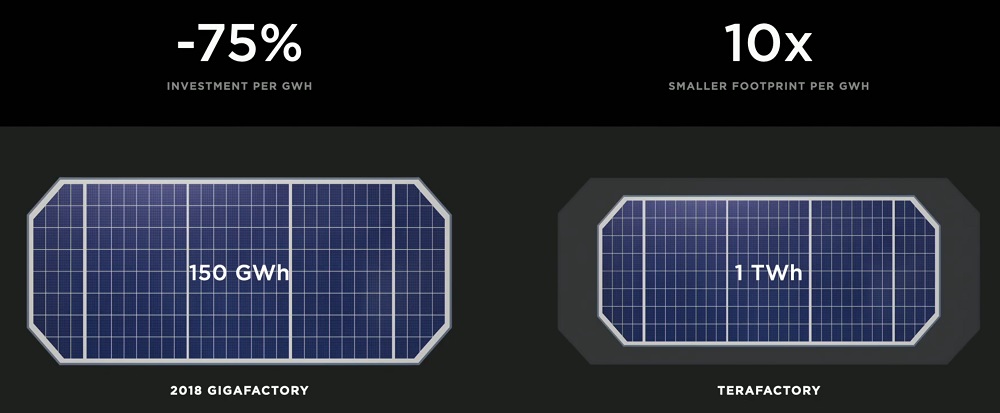

In order to produce the vast amount of battery storage they say will be required, Tesla intends to build factories that annually manufacture batteries on the terawatt-hour scale. Because of all the advancements they’re making these will supposedly have their capital costs reduced by 75% per gigawatt-hour of annual production capacity and be 90% smaller:

The size reduction will come from simplifying processes and improving automation. Because modern automated factories don’t even have people with clipboards walking up and down between machines, I believe him when he says the factory size will be much smaller. I hope he’s right about the capital cost reduction, because that’s important for bringing down the price of batteries.

Much Cheaper Batteries

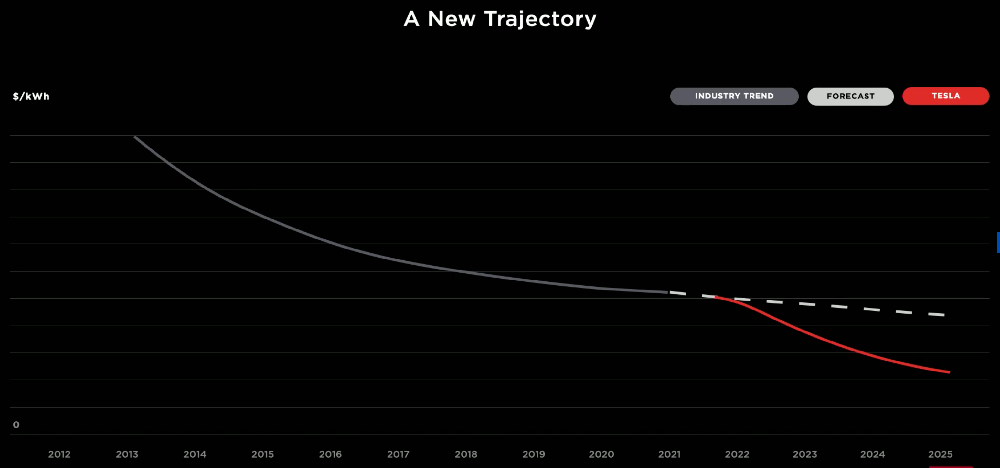

To stay in business and at least one step ahead of the competition, Tesla hopes to dramatically reduce the cost of batteries. They say Tesla have a plan to cut the price by more than half, although it’s hard to tell from the graph below as they neglected to put any numbers on the y axis:

A cynical person might say there are no numbers so Tesla can fill them in after the fact, but I’m sure the numbers were there. They were probably just knocked off after Elon Musk hit them with one of his balls of steel.

Elon comes straight out and tells us they intend to drop the price by 56% by 2025, but they never actually give the current figure Tesla says they are going to cut. It may be $100 US a kilowatt-hour since Elon predicted batteries would cost that much soon. So soon, in fact, he predicted Tesla would be at that point about a year ago. As far as I can tell, Tesla batteries are around that now.

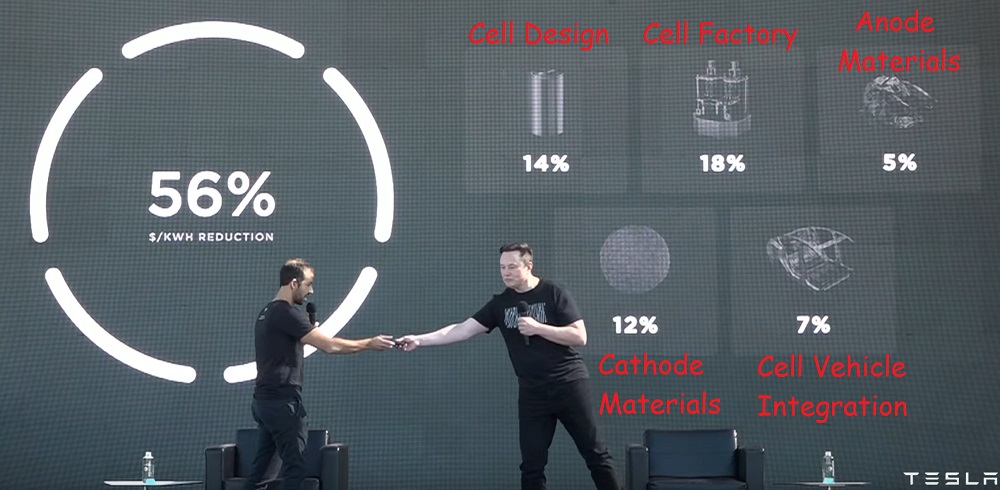

Here’s a shot of Elon Musk and Drew Baglino, Tesla Vice President of Powertrain and Energy Engineering, in front of a graphic showing a breakdown of how savings in 5 areas will total to give a 56% reduction in the cost of batteries per kilowatt-hour:

In the interest of fairness, I’ll point out Tesla didn’t label the areas with red Comic Sans typeface — I did that.

The 5 areas they claim Tesla will make savings in are:

- Cell Design — Building a larger & better tab-less battery cell

- Cell factory — Reducing energy use and waste.

- Anode Materials — Low-cost silicon will be used.

- Cathode Materials — Expensive cobalt will be eliminated and production simplified.

- Cell Vehicle Integration — Reducing the effective cost of vehicle battery packs by having them provide structural support.

Cell Design: Tesla’s new battery cell will be larger and cheaper per kilowatt-hour. It’s called a 4680 cell because it’s 46mm wide and 80mm long. Normally, making cells larger reduces the rate at which they can be charged because the energy passes through one connection point called a tab. So, Tesla got rid of it and these cells will be tabless with dozens of connection points. This will allow vehicles using these cells to still be supercharged while reducing cell cost and simplifying manufacture.

These changes will apparently increase the amount of stored energy per kilogram of battery pack by 16%. But I can’t be certain because the figures weren’t given with enough context for me to completely understand what they were talking about. When dealing with people who are fond of rubbery figures it’s wise not to take anything at face value.

Tesla are currently producing these cells in a pilot facility. They say it will take about a year to reach a 10 gigawatt-hour annual output. Actual production plants may have 200 gigawatt-hours or more of annual output.

Cell Factory: Their new cell factories will eliminate many production steps; reducing costs, time, energy use, waste, and required space.

Anode Materials: The anode is the battery electrode that electrons flow out of when it’s discharged. To lower its cost Tesla will use silicon similar to what’s used for solar cells, grind it up, stick it in an elastic gel that can cope with the fact that it expands and contracts when used, and shove it in battery cells. They say this is much cheaper than other, more complex, approaches and comes to $1.20 US per kilowatt-hour. This may increase energy density by 20%, but I take that claim with a grain of salt.1

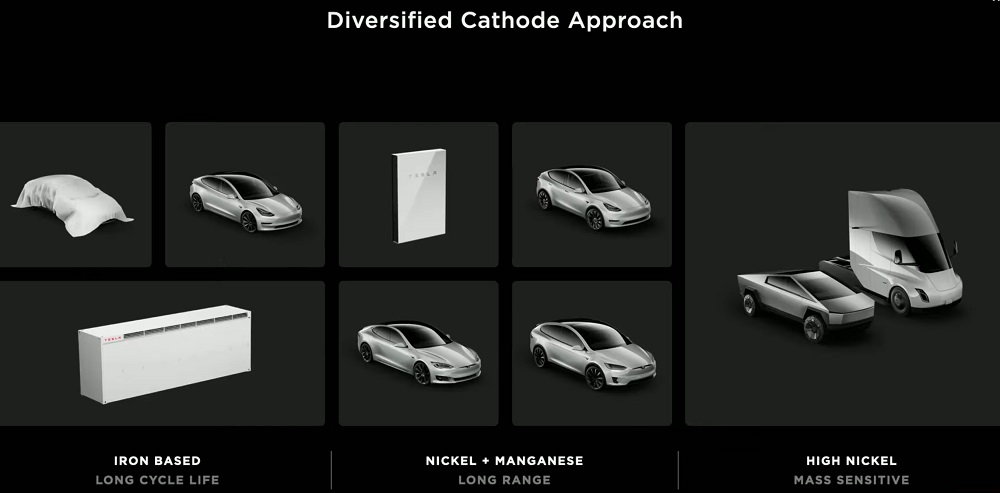

Cathode Materials: When a battery is discharged the cathode is the part of the battery electrons flow into. To reduce costs Tesla will eliminate the most expensive metal use for this part, which is cobalt. Nickel is better for energy density but isn’t as stable as cobalt and so removing it can result in faster battery degradation. This degradation will be countered in various ways and this graphic shows how Tesla will use different cathode compositions for different applications:

If you want a battery with a long cycle life and don’t care if it weighs more per kilowatt-hour, one with a lot of iron in the cathode can be used. For higher energy density, which can give a vehicle more range, a nickel and manganese cathode can be used. For even greater energy density a high nickel cathode can be used. (If you are wondering what the image in the top left corner is meant to be, it’s their future $25,000 US EV and not the ghost of internal combustion engine cars come to haunt them.)

My take from this is, if you are buying a long-range electric vehicle, don’t assume its battery warranty will be better than that of a shorter range vehicle.

To further reduce costs Tesla will simplify cathode production by eliminating some steps and improving others.

Cell Vehicle Integration: Tesla intends to reduce the cost of its vehicles by producing the frames in three main parts:

- The front bit.

- The back bit.

- The battery pack that will hold them together and give them strength.

Making the entire front and rear sections in one piece is very difficult because they’re made of aluminium and not dried toothpaste. The process requires the largest aluminium die casting machine in the world.

The front and rear sections will be held together with the battery pack, which will provide strength. Battery packs have to be strong anyway to resist impacts and protect occupants, so Tesla are going to make use of this to provide structural support for the vehicle, allowing them to reduce the weight of other parts of the frame.

Recycling

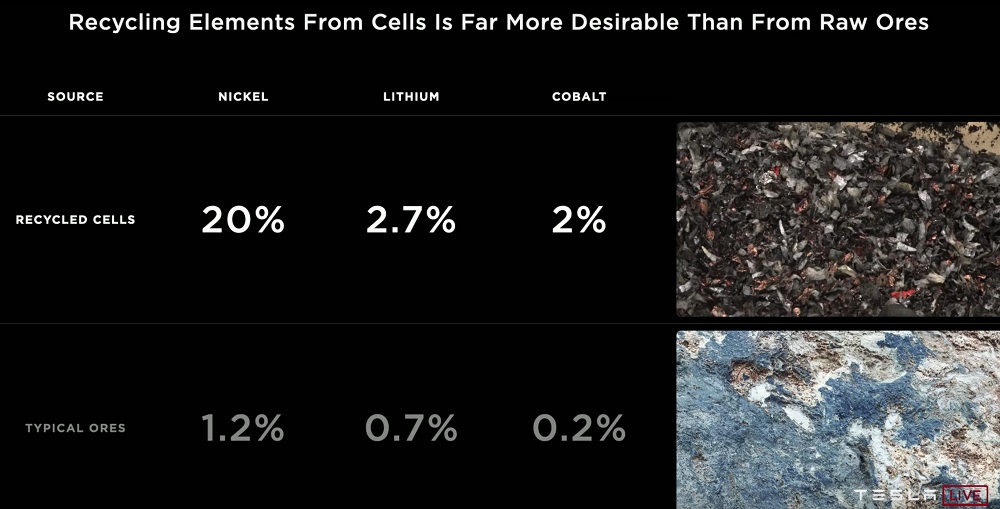

Elon said in the future all batteries will be made from recycled old ones, but at the moment there aren’t enough old batteries for that to be possible. It was also said that recycled materials will be used because the desired materials concentration is higher than they are in ores. This isn’t always correct, as sometimes recycled materials are contaminated in a way that makes it cheaper to use fresh material, but I hope this is correct.

I’ve reproduced the image below just to show how little lithium and cobalt there is in an average cell as I’ve noticed some people worry way too much about the price of these materials. They are only a small portion of the total cost of batteries. When manufacturers blame high raw material costs for batteries not falling in price as they promised they are generally lying.

Example Australian ore concentrations: Nova nickel mine in WA 1.85%. Greenbrushes lithium mine in WA 1.2%. Grawler mine ore in SA 1% cobalt.

A Self Driving EV For $25,000 US

With all the battery cost reductions Tesla will be making, Elon says in three years time they will produce a fully self-driving electric vehicle for $25,000 US. At the current exchange rate plus GST that comes to $39,000 Australian. While that’s a little pricey for someone in my stinginess bracket, its running costs will be much lower than for any similar-sized petrol or diesel vehicle. Unfortunately, while we can hope they have improved, given Tesla’s past performance with getting things done on time it may be 4 years before it’s available in the US and longer before you can get the EV here.

I have no trouble believing that someone will have autonomous vehicles that are permitted to drive on roads in three or four year’s time, I just find it very hard to believe whatever Elon Musk says on the topic given the large number of things he has said about that have turned out to be untrue. So I’m automatically primed to call shenanigans whenever he mentions it.

Tesla Now Hiring

The figure given for battery manufacture employment at the 20 terawatt-hour a year level was 2.8 million. A message repeated a number of times through the presentation was Tesla wanted talented people to come and work for them. This certainly makes it seem as though Tesla is rapidly expanding. After all, as Tesla workers are usually reasonably young, they probably aren’t just trying to make up for those they lost to the plague.

Improving worker productivity might be why Elon Musk wants to stick computer chips in people’s brains. While it might sound weird, it’s not that strange given we already have cochlear implants. But what I find really odd is how another billionaire, Bill Gates, is spending money to develop vaccines to save lives and people accuse him of using it as a front to inject mind-controlling computer chips into people, but when Elon Musk says, “I will put a computer chip in your brain,” people think it’s great.

Good Luck, Elon

Provided Tesla can pull off the cost reductions Elon is promising they may stay one jump ahead of the competition. If Tesla can produce battery cells at a lower cost than anyone else their stock may even be worth its current evaluation. But I don’t see them as having anything that will give them bulletproof business protection. Tesla’s main advantage seems to be they are big and currently growing bigger. But this may still be enough for Tesla to dominate the battery and EV market for decades to come, if combined with skilled management.

But if they do get eaten alive, I hope it’s because Tesla met all their cost reduction goals but the competition did even better.

Original Source: https://www.solarquotes.com.au/blog/elon-musk-battery-day-tesla/