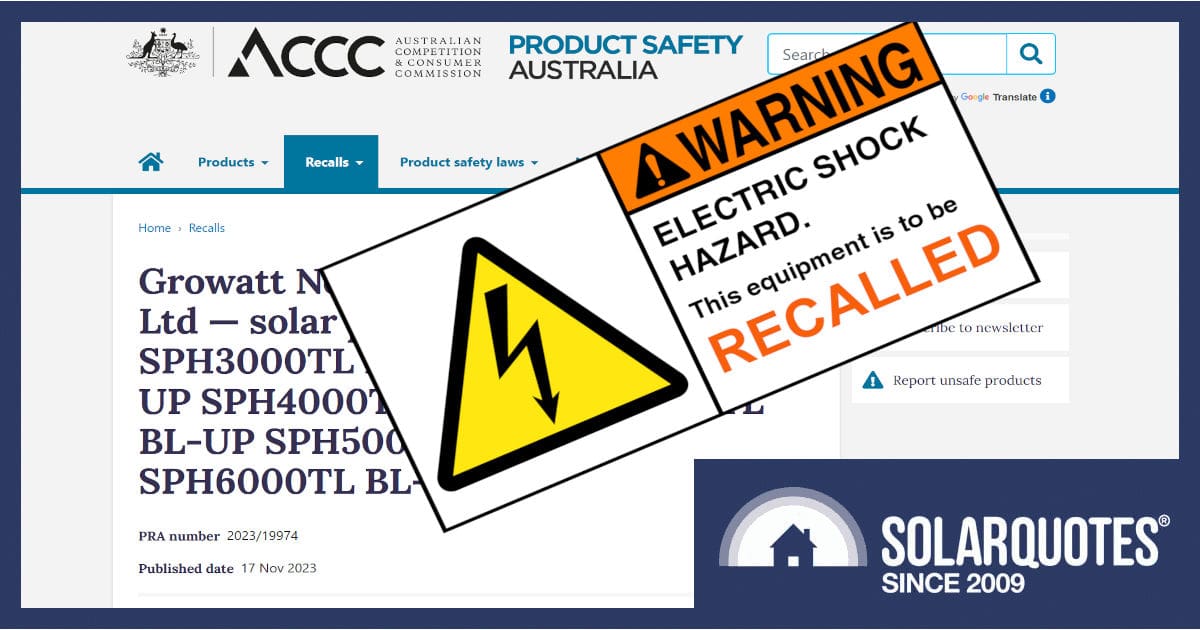

ACCC Recalls Dangerous Growatt & Goodwe Hybrid Inverters

The ACCC has issued an urgent recall for some Growatt & Goodwe hybrid inverters that can expose the user to a live, hazardous voltage.

Recent incidents have raised concerns about the safety of these devices when the backup port, often referred to as the Emergency Power Supply (EPS) port, is left exposed.

Read on, and I’ll explain the potential risks.

The Danger Of Sloppy Inverter Design

Battery-backed hybrid inverters are currently very popular. These are officially known as Multiple Mode Inverters (MMIs) and are not technically a true uninterrupted power supply (UPS). However, they will generally provide enough power to keep the lights on during power outages caused by grid failures.

Many series hybrid inverters have big fat plugs to connect the wiring. They’re great if you have to change a dead unit over, but many electricians will explain they’re fiddly to wire up and demand very specific cable1 and looks like a mess when finished.

So, there are two AC plugs or ports on a series hybrid. The GRID port, which, as the name suggests, interacts with the incoming mains supply, and the EPS port provides a 230 Volt AC output to supply power when there’s a grid outage.

The Hazardous Scenario

Some hybrid inverters activate the EPS port by default, making it live as soon as the device is operational. However, if you have a hybrid unit installed but are yet to buy batteries or have the backup circuits connected, a critical oversight has been observed;

Failure to fit the supplied output connector, leaving the Back Up Port terminals exposed.

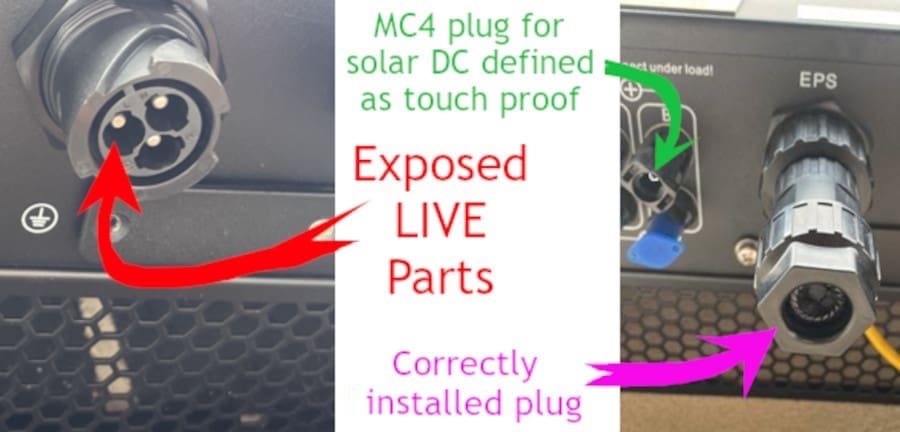

The large opening in the EPS plug means an official test finger can contact the metal pin, unlike an MC4 connector for solar input, which should ideally be blanked off as well.

Exposed live parts: the cardinal sin of electrical practice.

Leaving the plug off poses a serious risk of electric shock, as it allows direct contact with live parts. Electricians and Electrical Inspectors have a responsibility to ensure that all terminals of equipment comply with the safety standards outlined in AS/NZS 3000. These standards mandate preventing access to live parts before energisation, as detailed in AS/NZS 3000:2018 Clause 4.1.2 (c)&(d).

You must not be able to stick your fingers anywhere there is a metal pin which might give you an electric shock.

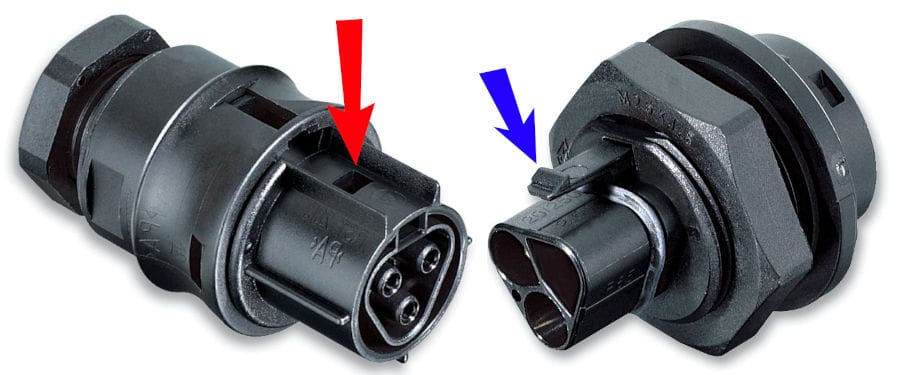

These plugs have a twist collar to stop them from falling out, but the rules stipulate they must be secured using a tool for access.

Safety Requirements

Electricians should meticulously follow the manufacturer’s instructions, ensuring that all parts, covers, and connectors provided are correctly fitted, leaving no exposed live parts.

And by the same token, electrical inspectors should look carefully to identify unsafe situations, and ensure they are rectified. Any electrical equipment posing an electric shock risk must not be installed or energised.

15 years ago, I installed these compliant touchproof Wieland plugs on solar inverters. A small screwdriver in the red window depresses the blue tang when releasing them.

Complacency Is A Killer

Since inception, inverters have been supplied with AC plugs that are inherently safe. Because they’re designed to be touch-proof and only removed with a tool. As new manufacturers have entered the market they haven’t adhered to the same standards.

I have seen first-hand the qualified trades who just ignore the printed “quick install guide” because they’re often badly translated or too tiny to read. What’s needed are blindingly obvious warnings on the bag in which these connectors come in or tags on the inverter plugs themselves.

An Australian-made Latronics PVE, just like this one, still powers my house with a touch-proof AC plug to connect it. Similarly, vintage SMA SunnyBoy units were touch proof but not secured with a tool.

Manufacturer Non-Compliance Prompts Recalls

Some manufacturers have connectors that can be removed without the use of a tool, allowing access to live parts. This is a basic non-compliance with AS/NZS 4777.2 Clause 2.3.3.1 and is a product issue that EnergySafe is actively working with manufacturers to resolve for the safety and compliance of the Australian market.

It’s embarrassing for Growatt and GoodWe, but interestingly, the extra attention has brought Sungrow out in a proactive series of updated social posts to explain what some of the random pieces of plastic they supply in the box actually do.

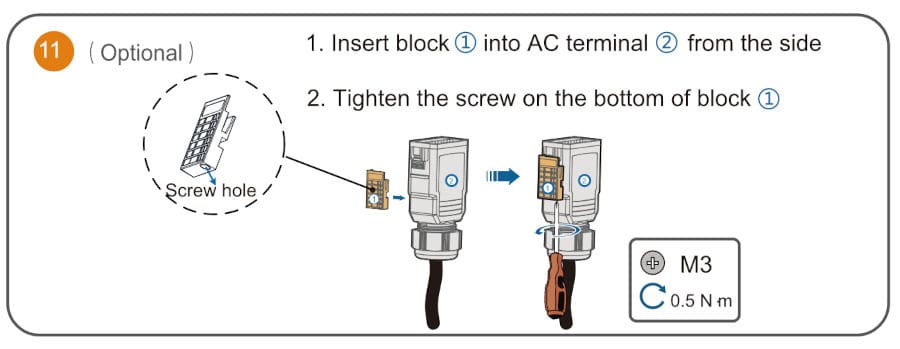

Manufacturers may provide purpose-designed locking mechanisms, such as the one shown in the image below, to prevent unauthorised connector removal, but unless there’s some awareness, these separate parts can end up chucked in the bin.

Note this leading manufacturer hosts these install instructions on their local website. They mention the lock device as optional, but in Australia, it isn’t. I have installed them, but I promise you that because they’re in a separate unmarked bag, many will be tossed away.

Check Your Inverter

Safety is paramount when dealing with electrical equipment, especially alternative supplies.

Confirm if you have a recalled GroWatt inverter, or a recalled GoodWe inverter, by checking these links for the ACCC’s recall notices.

If you have any other brand of hybrid it may also be worth checking if the plugs on it are secure and can’t be removed by inquisitive hands without using some kind of tool. Click this link to read a useful explainer from EnergySafe Victoria. If you are concerned, contact the original installer who should be happy to confirm whether all EPS ports have been secured properly.

Footnotes

- 6mm² and 16mm² multi-strand circular UV stable; is a special order at the wholesaler ↩

Original Source: https://www.solarquotes.com.au/blog/accc-recalls-hybrid-inverters/