Nerd Alert! Crunching the Numbers on the New 1000V Solar Standard

Whilst we usually try to make our blog posts understandable to almost anyone, this post will get technical, as I show, with numbers, why the new 1000-volt limit for residential solar makes life better for installers and homeowners alike.

Australian solar installers are celebrating now that the latest version of the Australian Standard for solar inverters – AS4777 – has allowed domestic systems to increase to 1000 volts DC.

My first inverter was, and still is a Latronics PVE 2500. Made in Queensland, it’s a basic box. With one high current MPPT input, the specifications were very inflexible.

You could have up to four strings in parallel, but a maximum of only 206 volts meant four 45 volt solar panels in series (4 panels x 45v = 180V) was the only string configuration; take it or leave it. This made things awkward when salespeople mistakenly contracted for 6 panels, leaving installers to explain to customers they had to spend $1800 for two more.

Australian Brutalist Icons.

Europeans Also Had Inflexible Inverters

It makes for swearing when the sticker on the side of an SMA SunnyBoy 2500 says 180 – 500VDC input, and your meter measures 200V, but it still won’t fire up. 45-volt nominal panels can be a little doughy on a hot summer morning when there are only six panels in series and two strings in parallel.

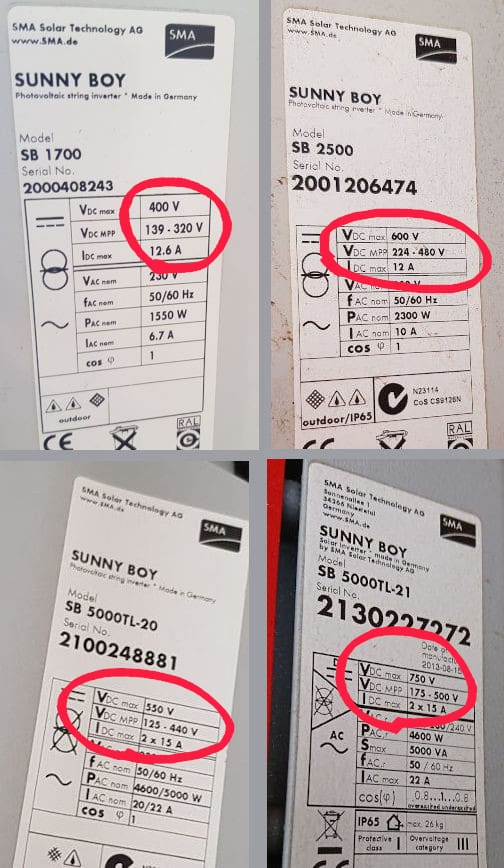

SMA Sunny Boy labels. Old transformer units above, transformerless below, with maximum voltages rising as models progress.

We soon learnt that despite being outside the allowable 500VDC maximum, a single string of 12 was the only option for these units, and SMA arrived at the same conclusion despite their reputation of being conservative about blowing up inverters. Because cold solar panels are more efficient, SMA had to handle overperforming arrays in sub-zero alpine Germany, but Australian heat made panels less efficient, helping SMA deliver Australian units with a 600VDC limit applied.

Now We Have Amazing Breadth

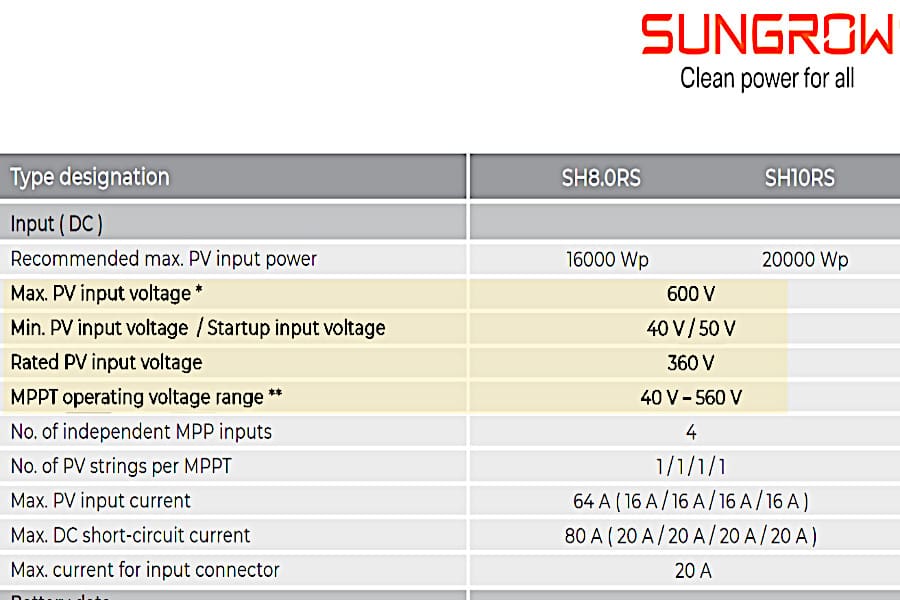

These days, inverters have wide operating windows. Starting at 40VDC, you can use a 2-panel (!) array or 13 panels for 600VDC—except if it’s a Sungrow 8 or 10kW hybrid series. Their 4 MPPT inputs have some funky little problems with needing a relatively balanced voltage, not more than 150VDC spread between them. I haven’t heard a good explanation yet for this issue.

Sungrow specs are impressive on the flyer, but making the thin text readable on a mobile screen is difficult.

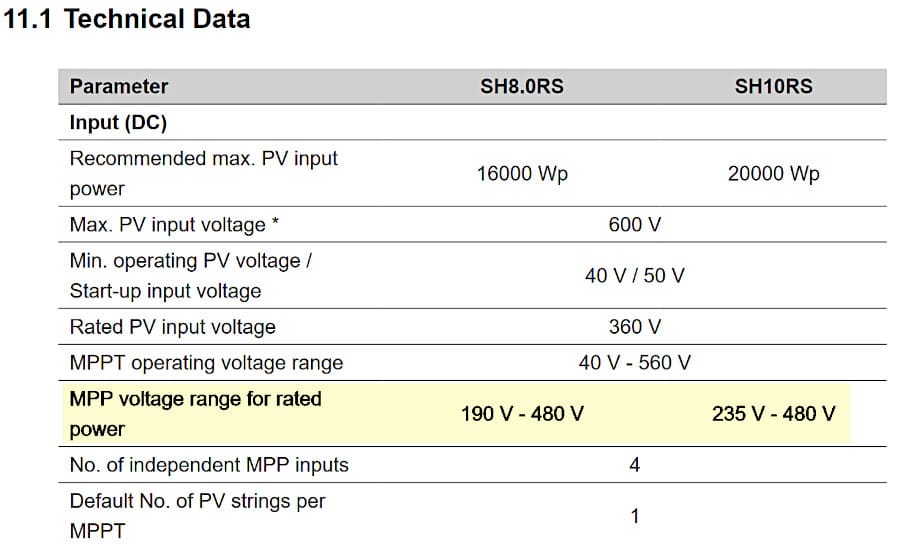

Sungrow flyer has asterisks** to refer to the install instructions, which show startup voltage is low, but rated output needs 6 or 7 average panels to really make things work.

Harmonisation Is Singing From The Same Book

When the last AS4777 was written, a spurious clause limited grid-connected inverter systems to 600V, creating a ludicrous situation where 1000v domestic systems were allowed by AS5033, but only if they were off-grid. With demarcation between standards now, they’re harmonised because they refer to, but don’t cross over, other related solar standards.

However, New Zealand is still using 20-year-old standards. They publish them, but the government fails to cite them in legislation. With 300+ updates needed, you’re more likely to sight a Tasmanian tiger there before citing AS/NZ4777.2024.

600 volts DC Suits Single Phase

Electrically, it’s not hard to fully load a 5 or 6kW inverter with a couple of strings under 600 volts. The Fronius Primo 8.2 is the only unit I readily recall as single-phase and 1000-volt input.

It’s actually a matter of inverter topology. Anything is possible, but inside the box, it’s easier to convert sub 600VDC to 230VAC, whereas 1000VDC is more efficient when you want 400VAC output for 3 phases.

Despite Enphase and their acolytes’ braying about the inherent safety of low-voltage DC 1, the vast majority of solar power systems use string inverters.

The real advantage is the ability to significantly oversize the solar array while staying under the standard 10kW inverter limit imposed by the networks.

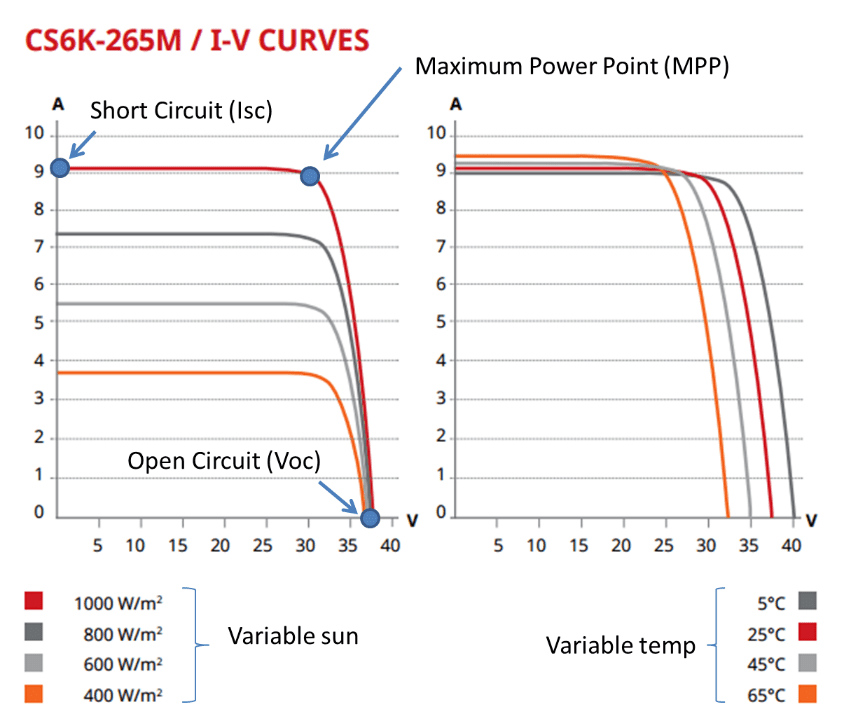

For those playing at home, multiplying 15 panels by 38 volts and arriving at 570 volts sounds simple, but once you uprate the output for low temperature at your locale, 13 or 14 panels become the practical limit.

This graph shows the effects of sunshine and temperature. Cold panels are more efficient.

Manufacturers have programs to make calculations easy, but when you add extra Australian rules, using software becomes essential to cover all the variables

Let’s consider a LONGi Hi-MO 5m 54c 420W:

- Maximum Power (Pmax): 420W

- Open Circuit Voltage (Voc): 37.3V

- Short Circuit Current (Isc): 14.12A

- Maximum Power Point Voltage (Vmp): 31.0V

- Maximum Power Point Current (Imp): 13.55A

1000 volts Puts More Power Into The Same Circuit

In round numbers, using 38V panels, a string of 14 in series will generate 532Volts open circuit (Voc)

Under ideal conditions, the array develops 5.86kW, that’s 434 volts maximum power (Vmp) multiplied by 13.5amps. (Imp)

Now, if we are allowed to increase to 1000VDC, then 24 panels develop 912Voc.

This means 24 panels develop 744Volts (Vmp) multiplied by 13.5 amps (Imp) so you have 10kW from the same circuit.

Using higher voltage on the same cable also offers lower losses.

Industrial Is Already 1000VDC

Higher voltage systems have been allowed on commercial building for years, provided switchgear is secured or inverters are in cages.

“Restricted access” has now been turned on its head though, “readily available” is now the key phrase in AS4777, so school kids could fiddle with the switches.

3 Phase Needs 1000VDC

As solar energy became cheap and large systems became much more feasible, we ran into problems.

Inverters designed for 1000V input couldn’t be “filled up” without exceeding 600VDC.

Parallel strings help, but current ratings for panels rose faster than inverter ratings, making parallel arrays impossible with cheaper units. Moreover, anything but the simplest roof could also make physical layouts problematic.

The upshot? Filling your roof with solar was more expensive because you had to buy more inverters to work under the artificial ceiling.

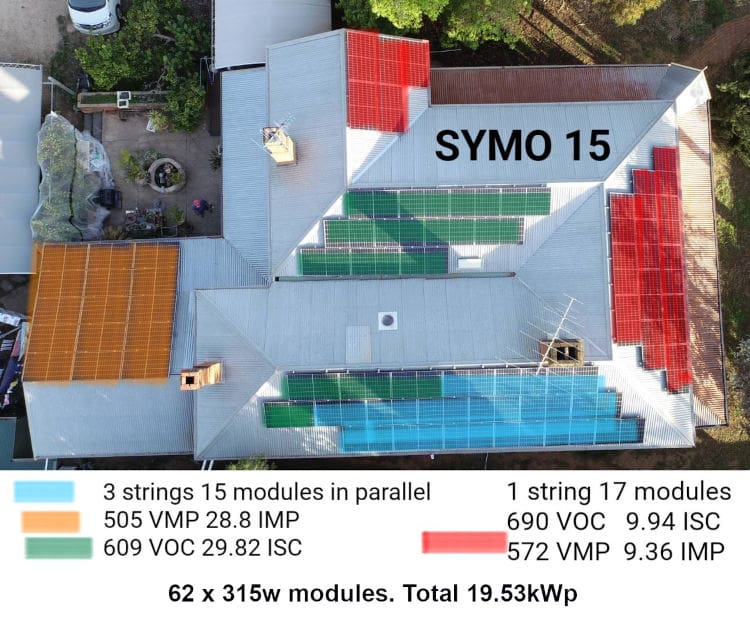

This design pushes a 15kW Fronius inverter to full capacity under new AS4777 rules.

If We Use The Old 2016 Rules:

In the complex example above, strings would be limited to 13 panels for a temperature-corrected 570Voc. A Sungrow inverter would be stuck at 4 strings of 13, an underwhelming total of 52 panels and 16.38kW

The inimitable Fronius Symo handles 3 strings in parallel for channel 1, then 2 strings paralleled for channel 2, so the total could be brought back up to 3 x 13 + 2 x 12 = 63 panels total…

However, while using an extra parallel string solves the electrical design problem, it also adds another panel. This is great news, except the physical arrangement on the roof would no longer work because there are 17 panels facing West in the example.

It’s like Tetris with a third dimension. Removing or adding a single panel can ruin a layout like this, causing much teeth gnashing for installers, designers and customers.

The Future Is Brighter with 1000V

These AS4777 updates have finally aligned Australian standards with global ones, allowing residential solar to reach its full potential. By increasing the allowable voltage to 1000V, the new regulations will make solar installations more efficient, cost-effective, and flexible.

For installers, this means less frustration and more design options. For homeowners, it means more power, lower costs, and faster payback on solar investments.

The future of solar in Australia just got a lot brighter—and a lot more powerful.

Footnotes

- Finn loves being teased, I hope ↩

Original Source: https://www.solarquotes.com.au/blog/as4777-1000volts-for-nerds/