The Dangers Of Giant Commercial Panels On Domestic Roofs

Recently I’ve seen a stirring in the solar marketplace. Big solar systems are great but the trend to giant oversized panels must be nipped in the bud. Please read on while I explain why commercial and industrial products don’t belong on domestic roofs.

Commercial and industrial (C&I) size power systems use megawatt hours of battery along with megawatts of panels, and those panels are mega-sized to suit freestanding frames on fantastic-sized farms.

I have written before about how much solar installers like handling these novelty oversized solar panels; the answer is they hate them.

For example, at 740 watts, the REC Alpha Pro XL is getting ridiculous

- 2.6 metres tall

- 1.26m wide.

- 44.1kg

It’s simply not something a human can handle, and even if it’s unpacked and placed using machinery, final fettling and clamping down requires at least two people.

No joke, these panels are to scale.

Domestic Solar Installations Rely On Manual Handling

A forklift might load pallets of panels on your trailer, but once the box is open, one person generally picks them up, cleans the packaging cardboard off the corners, stands them against something, and prepares the leads with stainless cable clips.

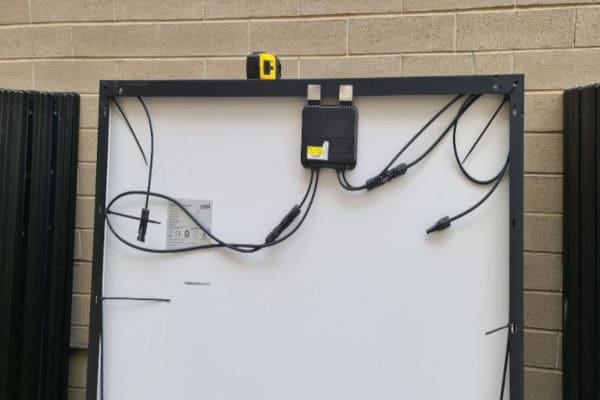

Leaning on a wall, this is where we figure out how to deal with cables before laying panels.

The next step is getting them on the roof. If the job is big enough (100+ panels) or difficult enough to warrant setting one up, this can be done using a conveyor, like a tile roofer would use, but larger.

Panel lifters are a great idea until you have to errect one.

Most solar panels are handed from one person on the ground to another on the roof.

Thousands upon thousands are just marched up a ladder, balanced in the crook of an installer’s arm. It’s one of those rites of passage you must demonstrate to the new installer when he or she baulks at the thought.

2 metres long is manageable, but I find the width critical. Once it’s beyond these at 1 metre, there’s much more leverage and weight on your head.

However, at 1 x 2 metres, this becomes a dangerous sail to hang onto in the wind and an OH&S liability nobody wants. That’s why the pictures on the pallet all specify two people to handle panels, which seldom happens in reality.

Difficulties Lead to Damage

What does happen in reality is damage to gutters, roofs and panels. Cumbersome solar panels are difficult to control, resulting in inadvertent scratches, holes and even glass breakage.

In this example, the roof cladding is actually backed with expanded polystyrene foam for insulation, making it very rigid. Though it’s impossible to dent underfoot, the extra strength makes these sheets prone to being punctured by the sharp corners of solar panel frames.

Surprisingly little effort was needed to punch holes in this roof

Sloppy installers or heavier panels just make matters worse, so this brand-new roof has dobs of polyurethane sealant to repair the damage.

Of Course There Are Exceptions

Some roofs really lend themselves to a long panel with three supports underneath it. You could argue that a large commercial and industrial panel is custom-made to fit this heritage cottage.

The flat roof shopfront extension on this old house looks weird.

From a technical perspective, the clamp zones on this panel are probably a little out of spec. It could simply be done with smaller panels and landscape orientation. However, another 24 matching ones are laid flat on the front of the building.

Wattage For Winners

There was a time when standard solar panel size was around 1600 X 800 millimetres. They were superseded by a similar height but 996mm width, and during the crossover period, the same manufacturer would offer the same cells in different panels.

You effectively had the same density, in terms of watts per square metre, but a choice of 195 vs 250 watts per panel.

For the installation below, the roof measured up well using small panels where big ones didn’t fit.

Four narrow modules offered 780 watts, it meant more capacity on the roof than three panels at 750 watts.

Some rules may have been fractured around the edges here.

These days, updated Australian Standards mean the corners hanging over the hips are frankly noncompliant, but with stout 40mm deep panel frames and a willingness to push boundaries, so much more has been fitted in.

Despite the horribly complex roofline, the bottom line on the bill is much better, too.

For this customer, the look of the power bill has always trumped the aesthetics of the building; he’s always been rapt with it.

195 watt panels arranged in 5 strings of 19 for a total of 18.5kW. This was a monster by 2012 standards.

There’s some elegance to a maximum-effort system, especially when it’s proved itself over 12+ years. Sadly, this one is slated for a roof restoration and replacement array, as a new hybrid inverter and battery backup for the dental surgery are in order.

Go Big and Go Home

More solar is more, and I applaud anyone who wants to maximise use of their available space. While modern solar panel frames are pretty thin, I’ve always found the generic rules are worth pushing with custom engineering if need be.

Sadly, you can’t buy custom-sized solar panels unless they’re horrendously priced flexible plastic ones for the bonnet of your car. What drives the dimensions of panels is simply the size of silicon wafers under the glass and the size of shipping containers.

Asking for bigger panels isn’t likely to get you a bigger system. Though there could be fewer electrical connections, the electrical and physical design restrictions imposed by large increments will likely prove worse.

And making the job hard for the people doing the work will never end well.

Original Source: https://www.solarquotes.com.au/blog/oversized-solar-panels/