SPI Energy will start 1.5-GW silicon wafer manufacturing site stateside by 2023

SPI Energy, the company that took over the former Sunergy solar panel manufacturing plant in Sacramento, California, and has been making Solar4America-branded solar panels out of the facility since March of this year, announced it has signed a letter of intent to secure solar wafer manufacturing equipment. The company is targeting delivery and production of solar wafers in the United States by 2023, originally planning to have 1.5 GW of annual wafer production capacity. SPI Energy wants to increase its wafer manufacturing capacity to 3 GW by 2024.

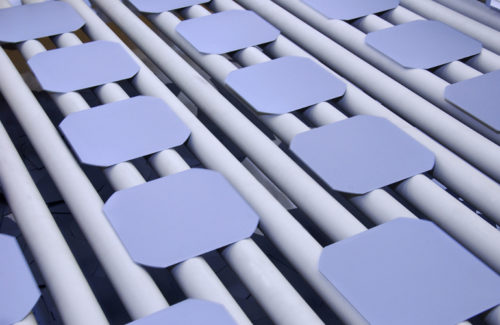

Wafers coming off the line at SolarWorld’s Oregon manufacturing facility. Archive photo from the Oregon Department of Transportation

This will be the first silicon wafer facility set up in the United States in nearly a decade. Wafers are the precursor to solar cells, which are then assembled into final solar panels. The United States does not yet have any cell manufacturing within its borders.

Although SPI Energy does already have a manufacturing site for its modules, it is largely assumed that it takes at least six to nine months to get wafer production started from the ground. SPI Energy’s late-2023 goal may be attainable, but U.S. polysilicon manufacturing plans aren’t expected to get restarted in time to supply an ingot manufacturer that will supply SPI Energy’s wafer process. But a first step is a first step.

SPI Energy, founded in 2006, is involved with EVs, solar and storage solutions and moved its global headquarters from China to California last year. Through its divisions SolarJuice (residential solar provider), SPI Solar/Orange Power (commercial and utility solar provider) and EdisonFuture/Phoenix Motor EV (EV sales), SPI Energy has operations in North America, Australia, Asia and Europe.

The company is expanding into wafers because of manufacturing tax credits included in the Inflation Reduction Act. Solar wafer manufacturers will receive $12/m2.

“I am very grateful to see the bill passed, as it will not only lower energy prices and help the country meet its climate goals, but boost U.S. manufacturing and create jobs. All of us at SPI are focused on scaling as fast as possible to provide customers with a more affordable, clean and resilient way to power their homes and lives,” said Xiaofeng Denton Peng, Chairman and CEO of SPI Energy, in a press release. “As a global expert in renewable energy industry and solar wafer mass production pioneer, we are able to start the state-of-art solar wafer manufacturing facility in USA with leading technologies.”

SPI Energy/SolarJuice entered the U.S. market after purchasing a list of yet-to-be-built residential solar contracts from bankrupt solar installer PetersdenDean in 2021. SPI Energy also acquired the Solar4America name from PetersenDean. In April 2021, SPI Energy launched a 360-W solar module under the Solar4America brand name. The company also launched an Amazon Store for Solar4America branded products.

SPI Energy began producing 450-W and 550-W solar panels at its facility in Sacramento earlier this year. The plant originally started at 200 MW of annual production, but the company planned to reach 1.1 GW by the end of this year.

<!–

–>

Original Source: https://www.solarpowerworldonline.com/2022/08/spi-energy-will-start-1-5-gw-silicon-wafer-manufacturing-site-stateside-by-2023/