5 Proactive Ways to Protect Your Solar Setup from Corrosion

A Growatt inverter near Ardrossan, South Australia

This article will explore proactive ways that you can protect your solar investment by slowing down and even preventing corrosion, enabling your solar panels to keep on giving right through to their (and maybe your) sunset years.

What Is Corrosion?

Corrosion is typically associated with metal, but the strategies discussed here for preventing metal corrosion are also applicable to other materials, like the plastic in junction boxes and cable insulation, or any materials exposed to harsh elements.

I’m not going to talk about “this or that study on the effects of corrosion” or give you any technical jargon. This article is about things that YOU, the average person, can do yourself and can be summed up simply as – making smart decisions and looking after your stuff so that it will look after you.

So, without further ado, here are 5 ways to proactively protect your solar setup from corrosion.

#1 Use a proven quality solar installer

There are no surprises there. Using a quality solar installer is the most important factor in maximizing your system’s lifespan, in my opinion.

Handle with care

Unless handled with care, corrosion can start its insidious journey on day one of your solar panels’ trip from the installer’s warehouse to the top of your roof. A quality installer knows that carrying and handling a solar panel incorrectly can cause micro-cracks , resulting in moisture ingress into the panel over time and deterioration to the cells or corrosion on the interconnecting conductors.

Galvanic corrosion prevention

A good installer focuses on your job rather than thinking about how quickly they can get off the roof and go home. They are more likely to read and understand the instructions that come with your hardware!

For example, when installing solar panels onto mounting rails, some thought should go into preventing galvanic corrosion between dissimilar metals. A good installer will use an anti-seize compound on the fasteners or an anti-corrosion coating designed for dissimilar metals. At the end of the job, no important parts should be left over, such as insulating washers that prevent direct contact between dissimilar metals.

Stopping rust on your roof

Good housekeeping on the roof is essential for minimizing corrosion on a steel roof. Leftover metal swarf from drilling holes for conduits and cable penetrations is a big no-no. Unless it’s cleaned off immediately, your roof will start to rust the moment the cowboys throw their ladders on the van and leave.

It doesn’t stop there. Correctly placed roof penetrations that are waterproof and prevent water pooling are a must. For a good overview, check out this post, but to be honest, you don’t have to if you use a good installer because they know their stuff. A solar company with a good culture and work ethic has it drilled into them. The boss doesn’t want his boys (and girls) returning later. It costs them money.

Preventing galvanic corrosion on a galvanized iron roof by using plastic or rubber bushes.

#2 Use appropriately rated and certified components

The main standards regarding corrosion prevention that a layperson might be interested in are IEC-61701 for solar panels, AS 4312 for mounting hardware, and the IP ratings of enclosures.

EC 61701 Photovoltaic (PV) modules – Salt mist corrosion testing

If you live in a coastal or high-humidity environment, this one’s for you. IEC 61701 is an international standard that addresses the resistance of solar panels to salt mist corrosion. It involves subjecting the modules to prolonged exposure to a salt mist environment to assess their corrosion resistance. Solar panels that meet the requirements of this standard are certified as suitable for coastal areas or regions with high salt content in the air.

It’s good to know that all tier 1 solar panels meet this criteria. If your solar panel datasheet has the certification, it will display it loudly and proudly. While you’re checking that, it would also be good to eyeball the warranty document to see if there’s any mention of exclusions due to corrosion.

For a more in-depth and entertaining take on the effects of corrosion on solar panels in a coastal environment, please read Ronald Brakels’ article. It’s an old one, but all the principles still apply.

AS 4312 Atmospheric corrosivity zones in Australia

This standard identifies corrosive zones within Australia (C1 to C5) that enable a solar panel mounting system manufacturer to warrant their product under certain atmospheric conditions. It may take some legwork to get solid answers because most warranty documents require the installer to install the product correctly based on the specified zone.

My advice is to talk to the manufacturer and ask for written certification by a third-party engineer showing that their product meets any relevant standards when installed in the particular zone where you live. Their answer may include modified installation requirements.

IP (Ingress Protection) ratings

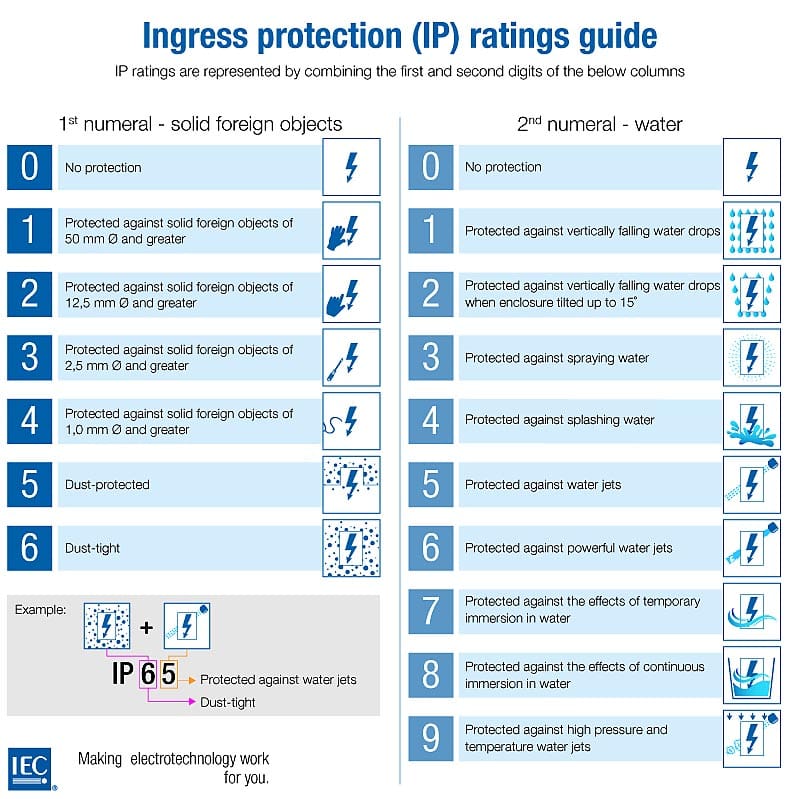

IP (Ingress Protection) ratings are a standardized classification system that indicates the degree of protection an enclosure provides against the intrusion of solid objects and liquids. The rating consists of two digits, with the first digit representing protection against solids and the second digit representing protection against liquids. Higher numbers indicate greater protection against the elements and, ultimately, against corrosion.

For example, an enclosure rated IP67 is totally protected by dust and protected against the effect of temporary immersion in water. Solar panels don’t have an IP rating, but any attached junction boxes will have one. Also, all other electrical enclosures, such as inverters, EV chargers and batteries, have an IP rating.

The official IP ratings guide. Image: IEC

#3 Locate hardware away from the elements if possible

Just because an electrical enclosure has a high IP rating, it doesn’t mean that it’s bulletproof. All components degrade and corrode faster when exposed to the elements. Most enclosures are not airtight, so the outside humidity will be the same on the inside of the enclosure when it’s not operating and producing heat that may counteract it.

There’s not much you can do about locating your solar panels away from the sun and rain. They won’t work quite as well sitting in your garage, but the rest of your system will do just fine. I strongly encourage you to install inverters and other components in the garage unless there’s a very good reason not to. I can guarantee they’ll last longer (crosses fingers behind back).

A fine example of where not to locate your inverter or switchboard. Image: Crap Solar FaceBook Group

#4 Maintain and keep your system clean

Cleaning solar panels is about much more than just getting increased solar production. Whether you do it yourself or get a professional, it gives you a chance to spot corrosion and stop it in its tracks. Corrosion loves dirt, grime, and other debris, such as leaf litter and bird droppings. Get rid of it. If you don’t know how, read your system manual, or preferably get professional help.

You should give inverters and other components the same respect. I’ve seen them used as a dumping ground for rags and other bits and pieces in the garage, encouraging a buildup of dirt, dust, and spider webs. This can cause corrosion directly or indirectly by blocking ventilation that dehumidifies components. Is that you? I can see you blushing.

Your solar panels don’t have to look like this to get any benefit from cleaning.

#5 Get a system inspection at least every five years

Cleaning and checking your solar system is great for all the above reasons, but let’s be honest. You don’t know what’s going on behind the scenes. Some states require a mandatory inspection by an accredited professional every five years, and I think it’s a bloody good idea, mandatory or not.

The inspector has much more knowledge about this than your good self, and their trained eye is likely to spot things you’ve missed. The inspection would involve closely examining and testing solar panels, mounting hardware, structural integrity, wiring, all electrical enclosures, inverter, battery (if present), and earthing system. They will likely pick up any telltale signs of corrosion, extending the system’s lifespan.

Testing your rooftop solar at least every 5 years can pick up unseen problems and extend the life of your system.

Prevention Is Better Than The Cure

Please look after your stuff. Prevention is better (and much cheaper) than the cure. Reiterating my 5 proactive ways to protect your solar setup from corrosion:

- Use a proven quality solar installer.

- Use appropriately rated and certified components.

- Locate hardware away from the elements if possible.

- Maintain and keep your system clean.

- Get a system inspection at least every five years.

Can you think of any more?

Original Source: https://www.solarquotes.com.au/blog/preventing-solar-corrosion/