Canberra Battery Test Centre Phase 3 Results: Zero Batteries Problem Free

The Canberra Battery Test Centre’s third phase of testing is complete. In fact, all their testing is now finished. They have shut up shop and published their final report. But to help you benefit from their work, I’m going to go over the results of the last eight batteries they put through their paces. Next week, I’ll provide an overview of all 26 tested and offer advice on how to avoid buying a bad one. But for now, I’ll compress that advice into just two words…

Be careful!

Over the past six years, the Canberra Battery Test Centre has found poor reliability in systems tested. To minimize your odds of having home battery buyer remorse, here is my advice in three compressed bullet points:

- Make sure the battery is from a reliable manufacturer that is likely to still be around if and when you need to make a warranty claim.

- Buy from a good installer who is happy to return as many times as it takes to fix any problems that occur.

- Make sure you know how to use the monitoring to determine how much the battery capacity has degraded over time.

This won’t guarantee you’ll have a problem-free installation, but at least any problems that do occur should be reasonably rapidly rectified. Note that none of the points above are likely to apply if you buy the cheapest battery available.

This article will concentrate on how well the latest eight batteries from the Test Centre’s third round of testing performed. I’ll give details, but I can compress it all into one word right now, and that’s…

Awful!

Not one was problem-free. The only good thing I can say is the average results are a little better than for the 18 batteries tested in earlier phases. But nothing has performed as well as the Sony Fortelion, which was among the very first tested and was still going strong at the end of testing after the equivalent of 10 years of daily cycling.

Test Centre Reports

The Phase 3 battery results are included in the Canberra Battery Test Centre’s final report:

But if you want the full story, you’re also going to have to go through reports 11, 10, and 9. But that’s all. If you go back any further in time, it will result in Phase 3 battery testing not yet existing.

Phase 3 Batteries

Phase 3 testing began in January 2020 and continued until March this year, giving a total testing period of 2 years and 3 months. The eight batteries tested were…

- BYD HVM 11.0

- DCS PV 10.0W

- Fimer React 2

- FZ SoNick

- PowerPlus Energy LiFe Premium

- SolaX Triple Power

- SonnenBatterie

- Zenaji Aeon

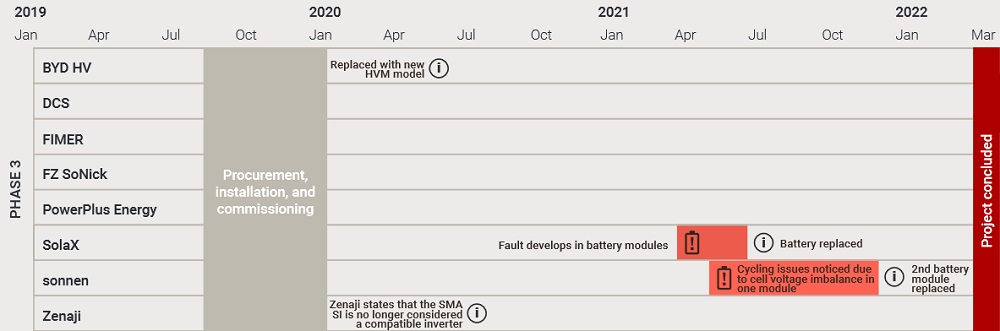

The table below is from the final report and shows some of the problems the batteries experienced:

Accelerated Testing

Two and a quarter years of testing isn’t long, given most home batteries are warranties are for 10 years and — fingers crossed — they’ll hopefully last 15+ years in practice. To get a more realistic picture of how they will perform long term, the Canberra Battery Test Centre used accelerated testing. This involved charging and discharging the batteries roughly three times more often than in normal household use.

The majority were fully charged and then discharged of all their usable energy three times per day. Each repetition is called a “full cycle” or just “cycle” for short. Home batteries are normally cycled an average of less than once per day, but special circumstances or joining a Virtual Power Plant (VPP) can increase this. For convenience, it’s generally assumed a home battery will be fully cycled an average of once per day. This means one will be cycled 3,652 times by the end of a 10 year warranty.

This testing isn’t identical to daily cycling as the batteries are charged and discharged faster than they would be in actual use, and this may increase battery capacity loss. But it is the best way to get rapid results on reliability and capacity loss. In the time available for phase-three testing, it would have been technically possible for batteries to have received the equivalent of 4.8 years of daily cycling but, because of various problems, only one managed this much testing.

Sample Size Of 1

Only one of each battery was tested. Because of this small sample size, we can’t reach any solid conclusions on how reliable individual batteries are. To be confident, multiple systems would have to be tested. The test results are evidence of the batteries’ reliability but not conclusive evidence.

Good Communication Is Key

Home battery systems normally have at least one battery module. For lithium batteries, these are rectangular metal boxes containing lithium cells. For other chemistries, there can be other weird stuff in there. For example, a car battery is stuffed full of lead and acid.

Modern home battery modules have electronics in them that function as the Battery Management System (BMS). Most home battery systems have a communications link from this to the inverter. This allows the BMS to control the charging and discharging of the module – overriding the battery inverter to protect the battery cells when necessary. Because the BMS is made for the specific module, it can optimize its performance1.

But there are also home battery systems that don’t have a link, which means the inverter controls the battery without any feedback from the BMS2. This is a simpler design, but without a communications link, the inverter can’t fine-tune charging and discharging as effectively. While this setup can work well, in testing it has often resulted in batteries being unable to supply the amount of usable energy manufacturers claim they are capable of.

Because of frequent problems, I suspect battery systems without communication links will be replaced in the market by those with them.

Different Kinds Of Faults

I’ve divided issues that arose in battery testing into five categories:

- Stealth problems: These are problems the Battery Test Centre noticed, but a typical homeowner could easily overlook for an extended time — until they become more serious.

- Major Problems: Major problems are anything that prevents the battery from functioning at or close to the level it should.

- Replacement parts: How many times were components replaced?

- Replacement batteries: How many times was the entire battery replaced?

- Capacity retention: An estimate of remaining battery capacity at the end of testing.

Note a stealth problem can become a major problem if it requires repairs or a replacement battery. Unfortunately, there will be many owners whose systems are suffering from stealth problems right now. Almost all modern battery systems are monitored online, which makes the number of times the Canberra Battery Test Centre was the first to discover a problem a concern. It makes online battery monitoring seem a bit bloody useless for consumers.

BYD HVM 11.0

BYD is a giant Chinese battery manufacturer. Testing began on an older model of home battery. But in June 2020, after several months of testing, BYD — quite sensibly — replaced it with a newer model as the old one was discontinued.

Despite coming from a company with plenty of experience producing battery systems, the BYD HMV 11.0 suffered two major breakdowns. In the month after it was installed, the battery refused to turn back on after a power outage. This was a serious problem because blackouts can happen to households at any time. BYD was able to help the Test Centre get it working again, but for a home battery, this fault would have required the installer to return to the premises.

The month after that, the battery developed a software fault and stopped working. BYD, again, helped get it going, but this problem took over two months to fix.

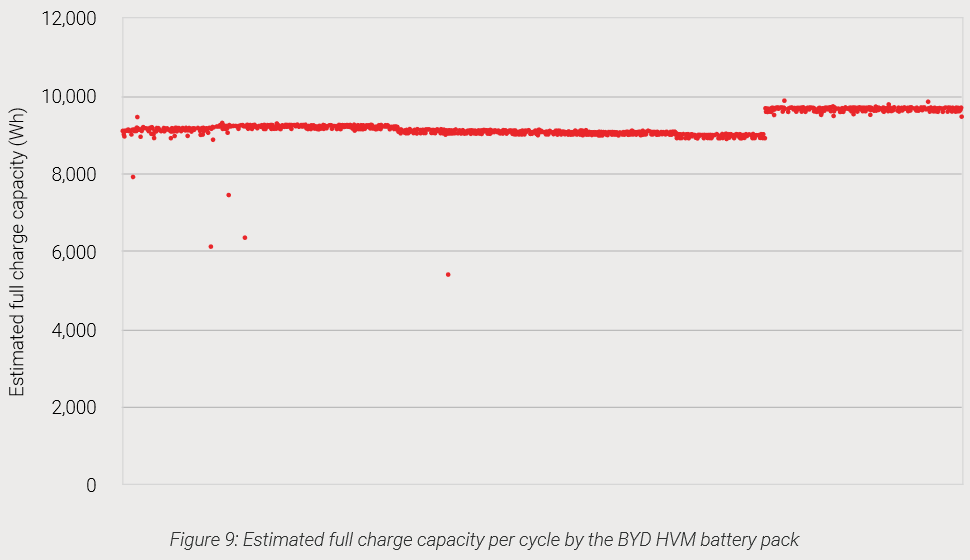

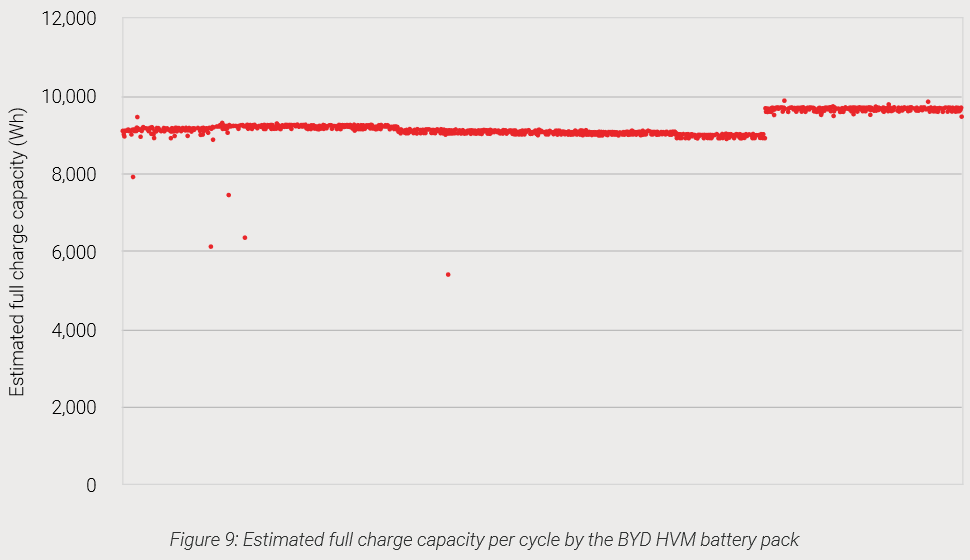

The capacity retention of the BYD B-Box HVM appears perfect, with no measurable decline in output after around 1,180 cycles, which represents around 3.2 years of daily cycling. After a firmware update3 in October 2021, the amount of usable battery capacity increased:

Note that even after the update, at just under 10 kilowatt-hours, it’s supplying less than the 11 kilowatt-hours usable energy storage the battery can provide according to its datasheet. So while it shows no sign of capacity deterioration, it may be occurring behind the scenes, and will only become apparent once it has progressed far enough.

I’m tempted to include only providing 90% of the usable energy it should as a major problem, but the performance of home batteries overall has been so poor this is actually a good result on average, so I’ll grade on a curve and let it pass.

- Stealth problems: 0

- Major Problems: 2

- Replacement parts: 0

- Replacement batteries: 0 (It was replaced with a newer model, but not because of a fault.)

- Capacity retention: No sign of capacity loss after the equivalent of 3.2 years of daily cycling.

DCS PV 10.0W

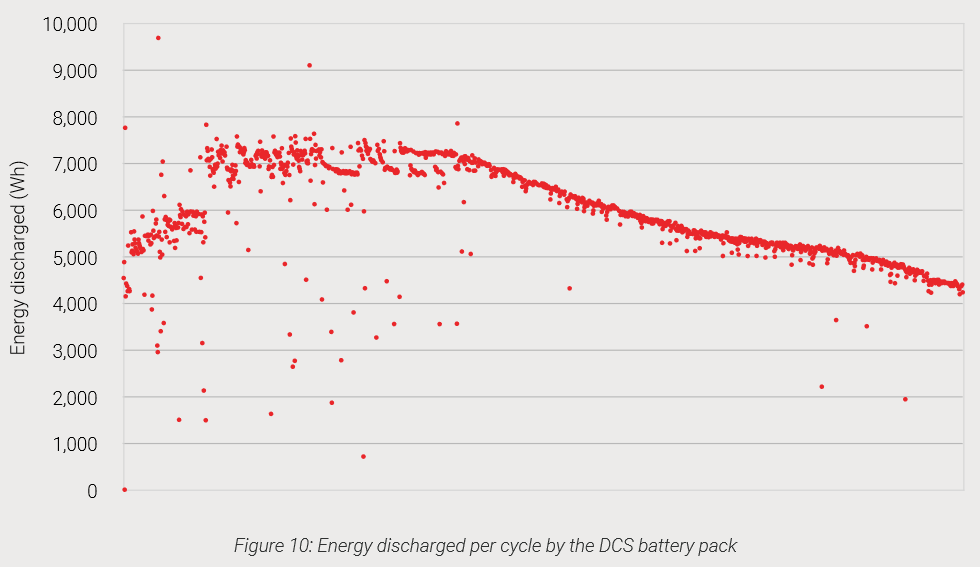

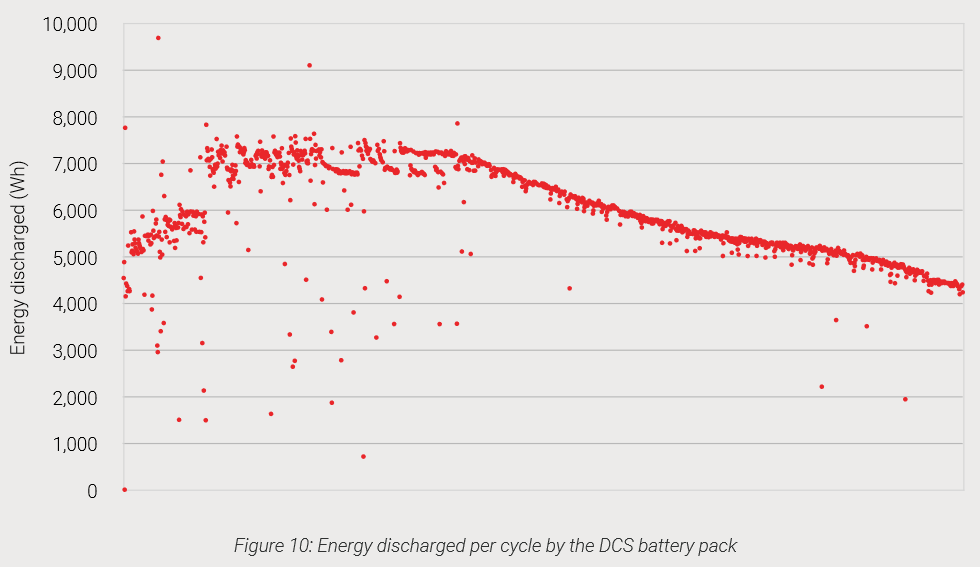

The DCS PV 10.0W4 battery system is made by Deep Cycle Systems in Queensland with imported batteries. It was installed with an SMA Sunny Island Inverter and doesn’t have a communication link from the Battery Management System to the inverter.

Unfortunately, this was one of the many cases where this arrangement didn’t work well and on average the battery supplied much less energy than DCS said it would. The Test Centre was able to improve this by cycling it over 8 hours, rather than the 6 used for the other lithium batteries, but energy output still averaged under 75% of what it should have been.

The battery has suffered a large decline in capacity. It was estimated to be at 57% of its original capacity after around 1,100 cycles or the equivalent of three years of daily cycling. At that rate, I suspect it wouldn’t have been long before the battery became unusable. DCS requested it be returned to them so they can examine it.

- Stealth problems: 0

- Major Problems: 2

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Atrocious at only 57% of original capacity after the equivalent of 3 years of daily cycling.

Fimer React 2

Fimer is a European company with headquarters in Milano. This is Italy’s 2nd largest city, and its population of 1.3 million would make it Europe’s Adelaide, except the coffee isn’t as good.

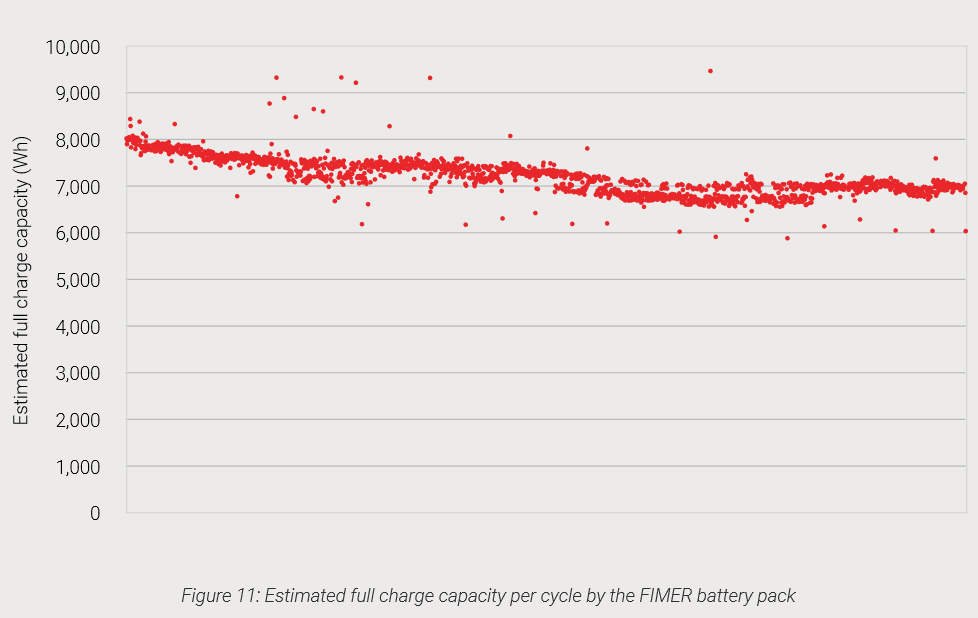

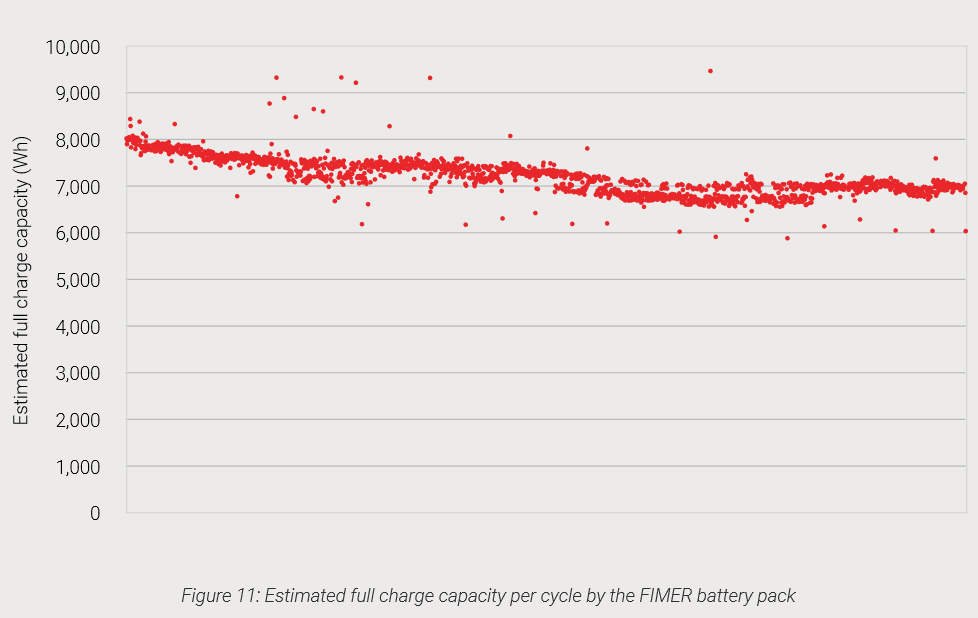

Fimer took over the ABB inverter company, so their battery is sometimes referred to as an ABB Fimer battery. The Fimer React 2 is a lithium energy storage system with its own inverter that can be AC or DC coupled. The one tested was DC coupled and had two 4 kilowatt-hour battery modules with a total of 7.6 kilowatt-hours of usable storage.

The battery had no problems until just prior to the end of testing when the Test Centre discovered one of the two battery modules had developed a fault, but at that point it didn’t stop it functioning. Fimer has said they are investigating the cause of the problem. This was a stealth fault, as no normal household would have noticed the problem unless it became a lot worse.

After around 1,740 cycles — the equivalent of 4.8 years of daily cycling — the batteries were estimated to have 86% of their original capacity. At this rate, they will have around 71% of their original capacity after 10 years of daily cycling. This is well above the minimum of 60% it is warranted for.

- Stealth problems: 1

- Major Problems: 0

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable and on track to be well above the 60% minimum capacity it’s warranty promises.

FZ SoNick

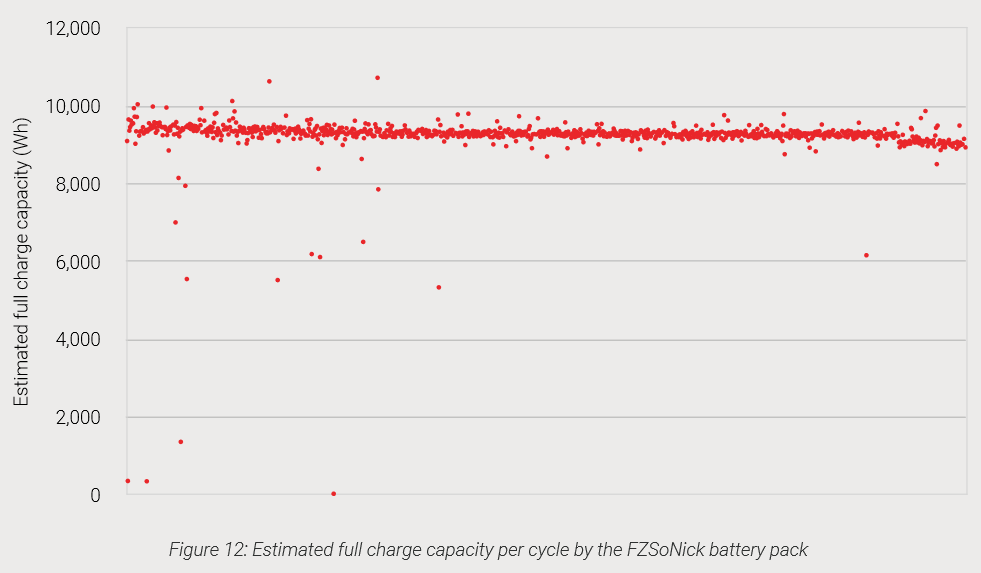

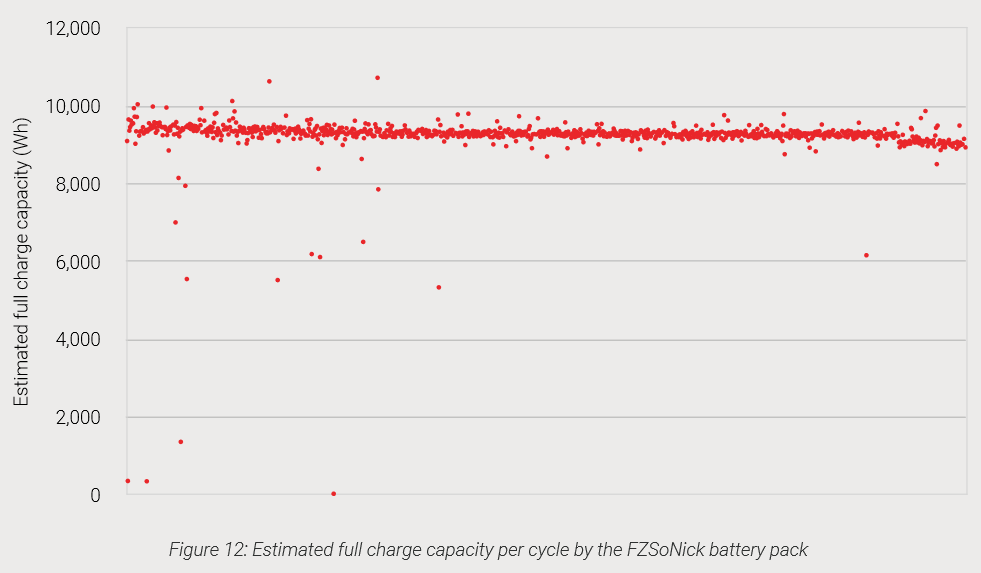

The FZ SoNick battery stands out for two reasons:

This molten salt battery operates at around 250 degrees. But if you’re thinking about getting one and making it serve double duty as a barbecue hotplate, the bad news is the outer casing is only a couple of degrees above room temperature. Despite remaining safe during operation, this battery chemistry is normally not used in homes. The manufacturer says they’re for industrial use, and I don’t think they’ll ever be widely used for residential energy storage.

The FZ SoNick battery used a Victron inverter, and when first installed it did not have a communications link between the Battery Management System and the inverter. But with help from the Australian FZ SoNick supplier, the Test Centre was able to set one up. This was probably a good idea, as the other three batteries in this phase of testing without communication links suffered problems.

It had a fault where the Test Centre noticed it wasn’t fully charging and only reaching around 80%. It was a stealth problem as it’s not the sort of thing the average homeowner is likely to notice. After they alerted the manufacturer, it was fixed online.

Because of its unique chemistry, it could not be cycled as rapidly as the lithium batteries and only racked up around 880 cycles. That’s the equivalent of 2.4 years of daily cycling, but because of its low power output, it’s unlikely to be fully cycled an average of once per day in most applications. At the end of testing, it had approximately 94% of its battery capacity remaining. If this rate of capacity loss was maintained, it would be on track to be at around 75% of its original capacity after 10 years.

I have listed the battery not fully charging as a Stealth Problem, as a typical household would be unlikely to notice it. Because I consider only charging 80% a major departure from normal operation, I’ve also included it as a major problem. On the bright side, it was resolved in a month, which is far better than some battery repair response times.

- Stealth problems: 1

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable as it’s on track to be at 75% after 10 years of daily cycling.

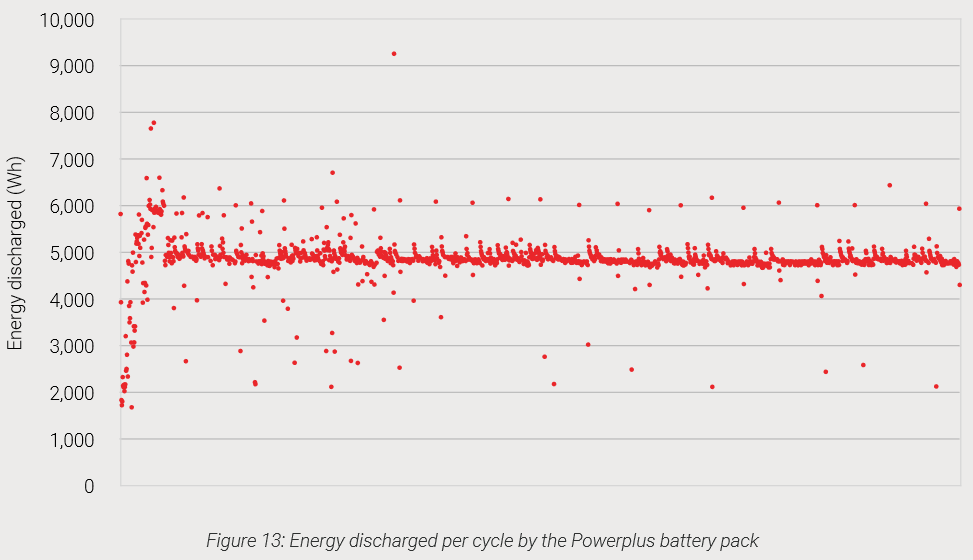

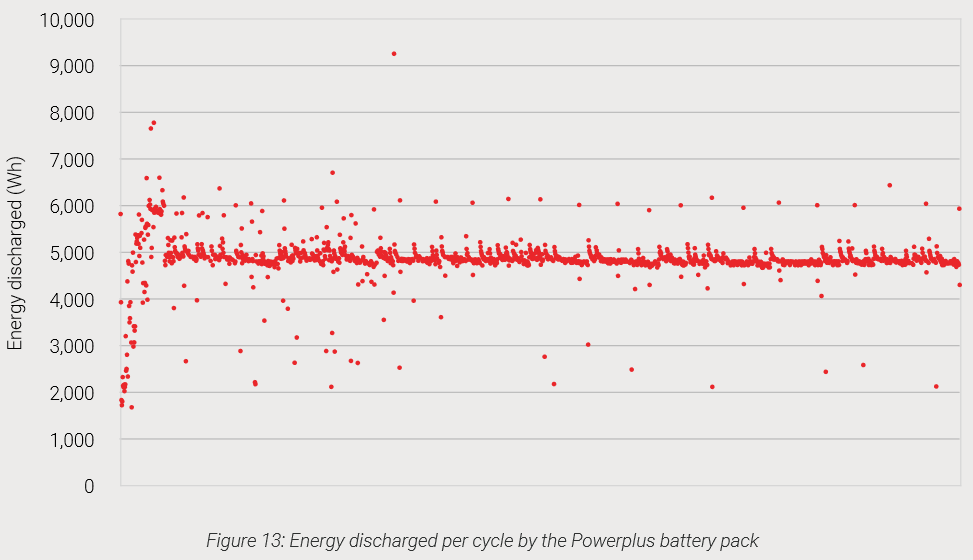

PowerPlus Energy LiFe Premium

The LiFe Premium from PowerPlus Energy is another battery without a communications link between the Battery Management System and the SMA Sunny Island Inverter it was paired with. The battery’s warranty requires it not to be discharged by more than 80%, but in practice it was difficult to determine its actual state of charge. Three modules with a total storage capacity of 9.9 kilowatt-hours were used. With a maximum 80% depth of discharge, that technically gave 7.9 kilowatt-hours of usable storage – but it normally provided under 5 kilowatt-hours per cycle.

After around 1,030 cycles, its capacity was estimated at 95%. If correct, that means it would be on track to be at around 82% after 10 years of daily cycling.

But despite this capacity, in practice the battery inverter could only extract about 60% of the battery’s usable energy per cycle.

While the battery supplied stored energy, it did not operate at close to the level it should have, so I count that as a major breakdown.

- Stealth problems: 0

- Major Breakdowns: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable in that it appears to have over the 60% minimum capacity it’s warranted for after 10 years of daily cycling, notwithstanding battery control issues.

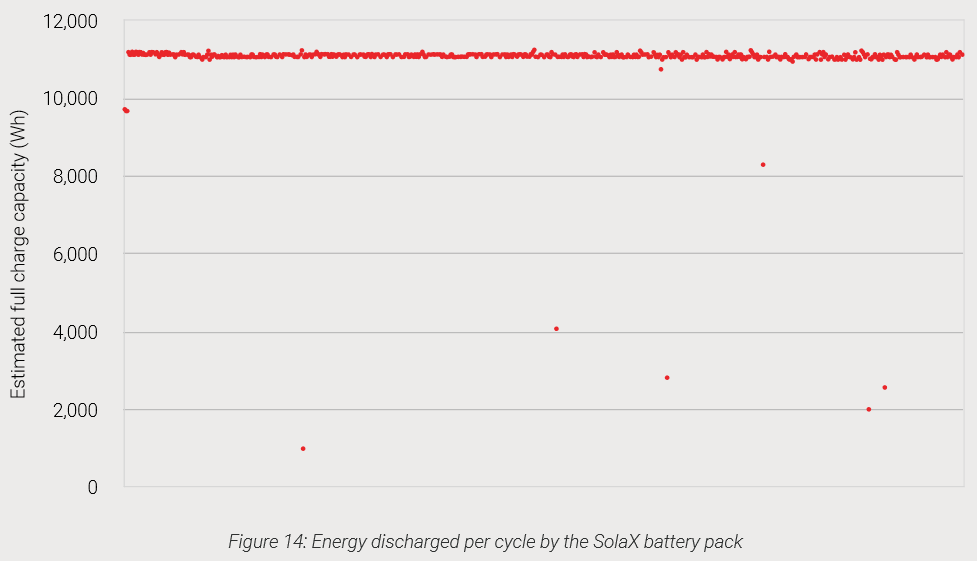

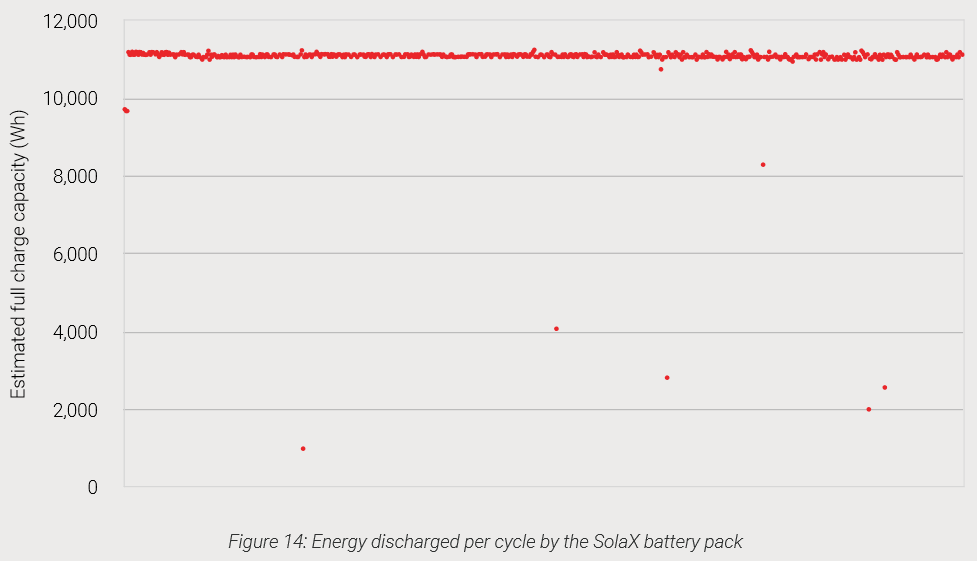

SolaX Triple Power

The SolaX Triple Power battery system worked well for the first year of testing, but then its ability to charge and discharge began to decline. SolaX attempted to fix it over the internet but concluded the battery needed to be replaced.

It performed well after that, but the new battery was only tested for around 600 cycles before testing ended. It had around 98% of its original capacity at this point. If this was maintained, it would retain 88% of its original capacity after 10 years of daily cycling, but the testing period of the replacement battery was too short to be confident the low rate of capacity loss would be retained.

Because a typical homeowner may not have noticed the problem that led to the SolaX Triple Power being replaced, I have called it a stealth problem. As it required the entire battery to be replaced, it’s also a major problem.

- Stealth problems: 1

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 1

- Capacity retention: Good for the 1.6 years of simulated daily cycling that was performed, but the testing period was too short for confidence.

SonnenBatterie

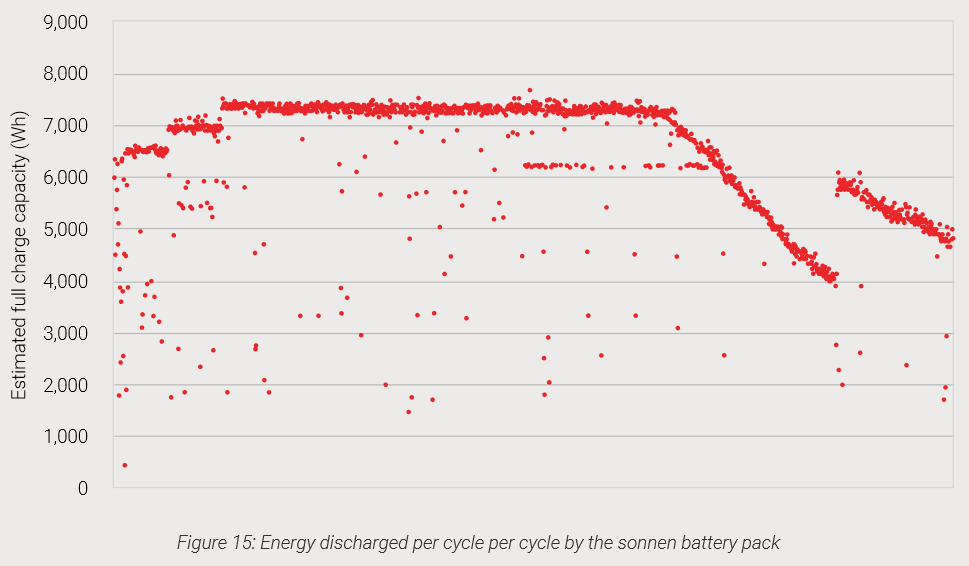

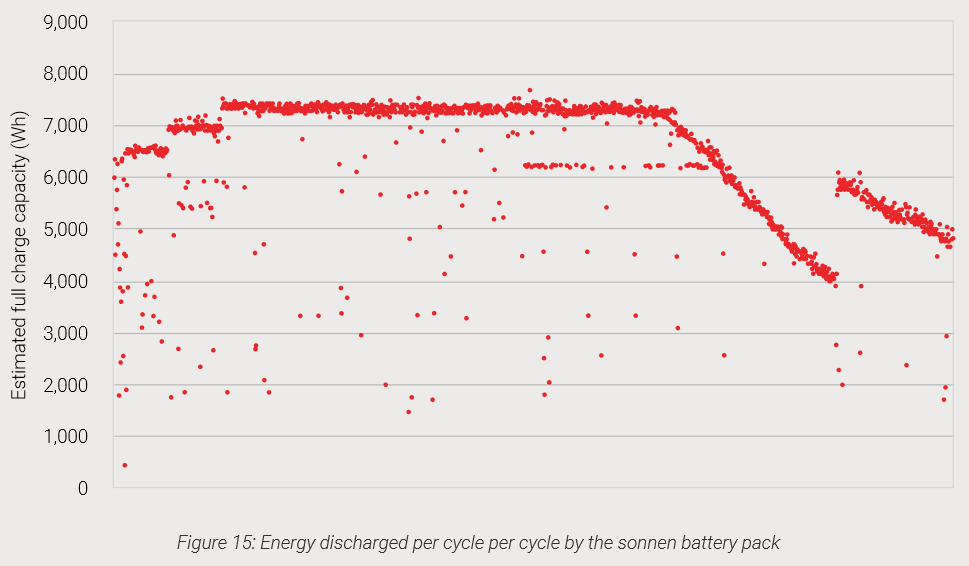

Sonnen’s SonnenBatteries are made in Europe using batteries produced in China. After some initial difficulties with its installation, the SonnenBatterie functioned well for 14 months of testing before developing a fault that caused its usable capacity to drop. The graph of its first 20 months of testing makes it clear when it happened:

Sonnen attempted to fix it online and then replaced one of its four battery modules. Six months later, they replaced a second battery module because it wasn’t operating as well as it should have.

The battery showed no signs of capacity deterioration in the 800+ cycles before the fault occurred or in the 160 cycles after half its battery modules were replaced. As its warranty allows the battery to be cycled 10,000 times while still retaining 80% of its original capacity, I am not surprised there was no noticeable loss of capacity.

- Stealth problems: 1

- Major problems: 1

- Breakdowns: 0

- Replacement parts: 2

- Replacement batteries: 0

- Capacity retention: Excellent over the limited number of testing cycles given.

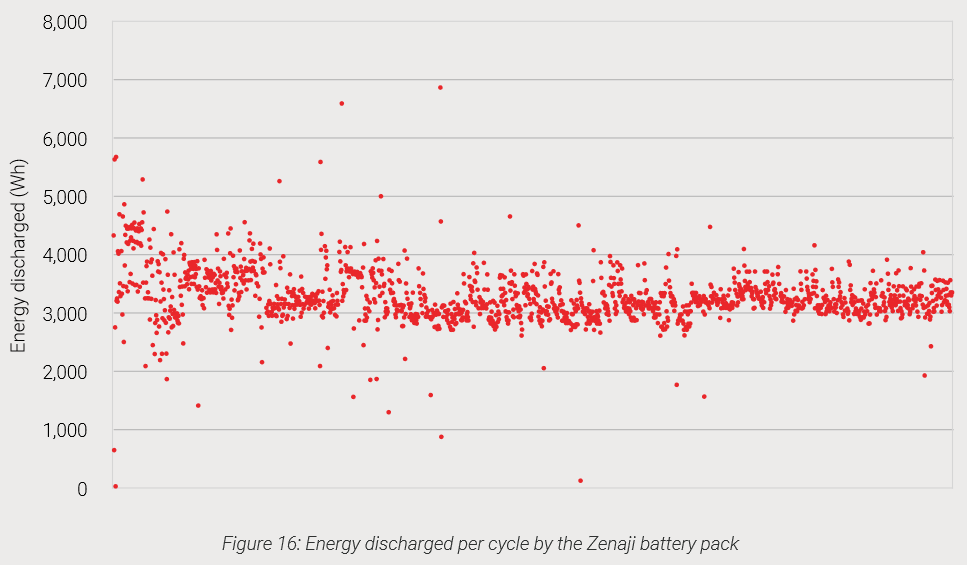

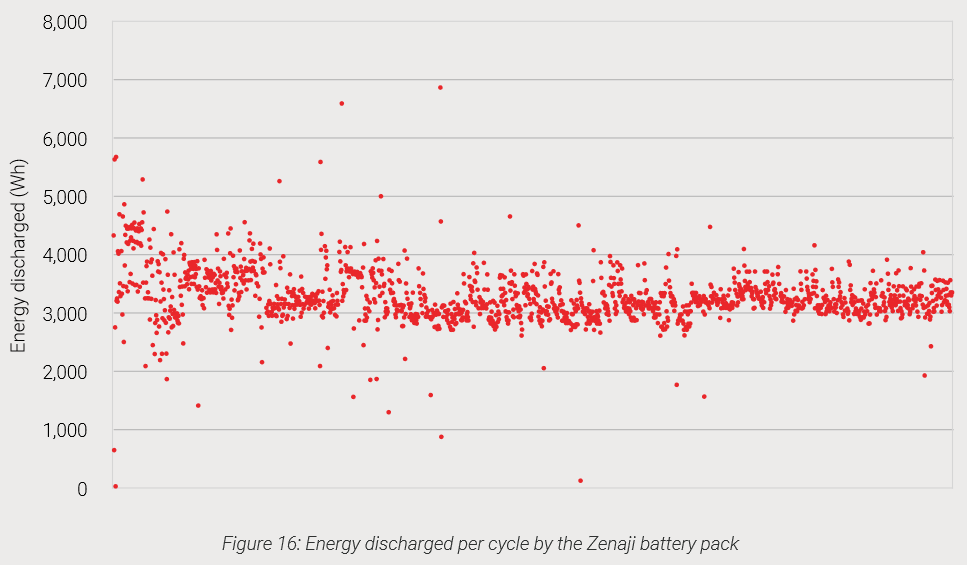

Zenaji Aeon

The Zenaji Aeon battery is another unit without a closed-loop communication link between the battery module’s Battery Management System and the SMA Sunny Island inverter controlling it. As with many other batteries, this has resulted in problems; in this case, they were pretty disastrous. From the start, the Battery Test Centre could not accurately measure the amount of charge stored and it only provided around one-third of the energy per cycle it should have.

Six months after the installation of the battery, Zenaji removed the SMA Sunny Island from its list of compatible inverters. In their 10th report, the Test Centre said testing would continue with the SMA Sunny Island inverter until Zenaji replaced it with a Victron inverter, but this never occurred and the SMA Sunny Island was used until the end of testing. No mention of a replacement Victron inverter was made in subsequent reports.

Because accurate measurements could not be taken, no estimate of battery capacity was possible.

While it’s possible the battery may have worked acceptably with a different inverter, the poor performance that resulted from using an inverter Zenaji said was compatible was still definitely a major problem.

- Stealth problems: 0

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Unknowable under given testing conditions.

Phase 3 Results — Best To Worst

Here is a sarcastic list of all the Phase 3 batteries that operated without a problem from their first day until the end of testing:

No, I haven’t accidentally left out the problem-free battery systems. There weren’t any. The one that came closest was the Fimer React 2, which didn’t develop a fault until just before the end of testing. It also had an acceptable capacity loss. While worse than two other Phase 3 batteries, it was on track to be at around 71% of its original capacity after the equivalent of 10 years of daily cycling, which is well above the minimum of 60% allowed by its warranty.

Below I’ve ranked the eight Phase 3 batteries from best to worse, in my opinion. This is only based on how well they performed in testing and does not mean one higher on the list is definitely better than one below it. It’s also subjective. In my opinion, a battery system that underperforms for years is worse than one that breaks down but is soon repaired or replaced. Of course, you may disagree. In this case, please feel to cut your screen up with scissors and rearrange the list as you see fit5.

From best to worse — in testing — the battery systems were:

- Fimer React 2 — One fault towards the end of testing. Acceptable capacity loss.

- FZ SoNick — 1 major problem was fixed in around one month, but it was a stealth problem typical owners may not have noticed for some time. Acceptable capacity loss.

- BYD HVM 11.0 — The battery broke down twice. No measured capacity loss during the period tested.

- SonnenBatterie — 2 out of 4 battery modules had to be replaced. No measured capacity loss.

- SolaX Triple Power — It broke down, and the entire battery had to be replaced. Capacity loss appeared minor, but not enough testing was done to be confident.

- PowerPlus Energy LiFe Premium — Only provided around 60% as much usable energy as claimed. Capacity loss appeared acceptable.

- Zenaji Aeon — Only provided around one-third as much energy per cycle as it should have. Capacity loss could not be determined.

- DCS PV 10.0W — Usable energy was, at best, around 75% what it should have been. Severe capacity loss.

The bottom three on the list were the only units without communication links between the Battery Management Systems and inverters. This result, as well as the results of previous phases of battery testing, makes me think communication links will become standard.

A Conclusion

While there is only so much that can be concluded from testing one system, it is possible to conclude the majority of home batteries installed two and a half years ago had major reliability issues. Next week I will give an overview of the Canberra Battery Test Centre’s entire six years of operation, along with some basic advice on how to avoid buying a bad battery.

Footnotes

- This configuration is also known as ‘closed-loop control’. The link from the BMS to the inverter closes the feedback loop, so the inverter can fine tune its output based on one or more real-time battery variables. ↩

- Also known as ‘open-loop control’. ↩

- A firmware update is a type of software update that affects the operating system. It was done online without any physical contact or new hardware involved. ↩

- Normally I would make fun of the fact that the “W” at the end of DCS PV 10.0W makes it look like it’s a 10 watt battery, but because I’ve matured as an individual, I’m going to restrain myself and draw zero attention to it. ↩

- For safety reasons, you should put your screen under water before cutting it. ↩

Original Source: https://www.solarquotes.com.au/blog/battery-testing-results/